Trusted by Commercial & Industrial Leaders

Understanding System Performance in Real Applications

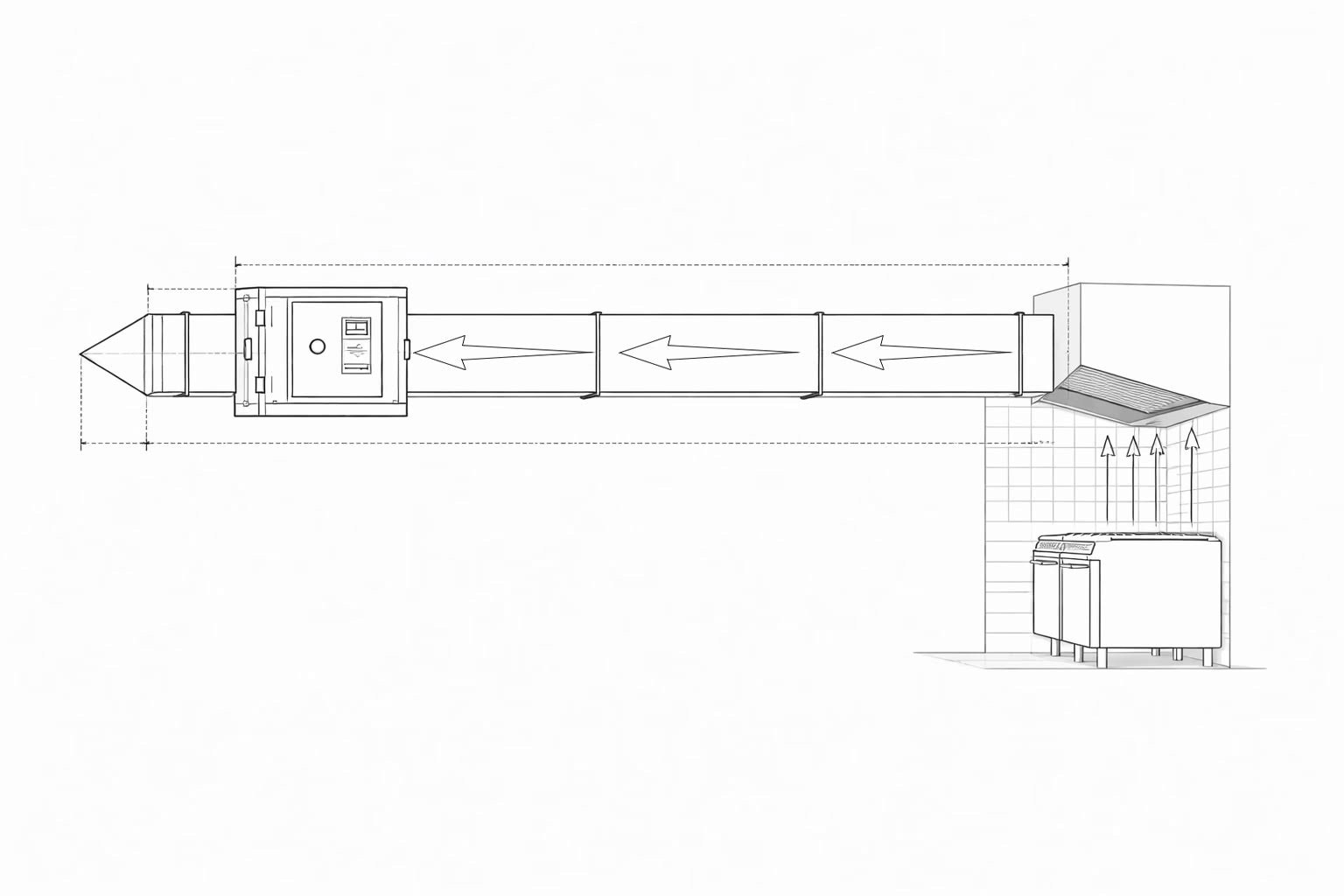

How it's works

Air is treated using UV light and ozone generated within the xDuct chamber; UV breaks down odorous compounds and organic aerosols through photolytic and ozonolytic reactions. Protected lamps require no cleaning and operate long life cycles, while safety interlocks ensure the unit only runs under extract airflow, maintaining effective grease and odour control with minimal impact on system performance.

xDuct UV Odour Control System

- Notes

on

Application

Used for odour reduction in commercial kitchen extraction ductwork.

Typically installed downstream of grease and particulate filtration.

Suitable for continuous-duty operation in high-temperature exhaust air.

Applied where chemical-free odour treatment is preferred.

Industries We Design For

Each system is engineered around real-world airflow, contaminant and compliance requirements.