Trusted by Commercial & Industrial Leaders

Understanding System Performance in Real Applications

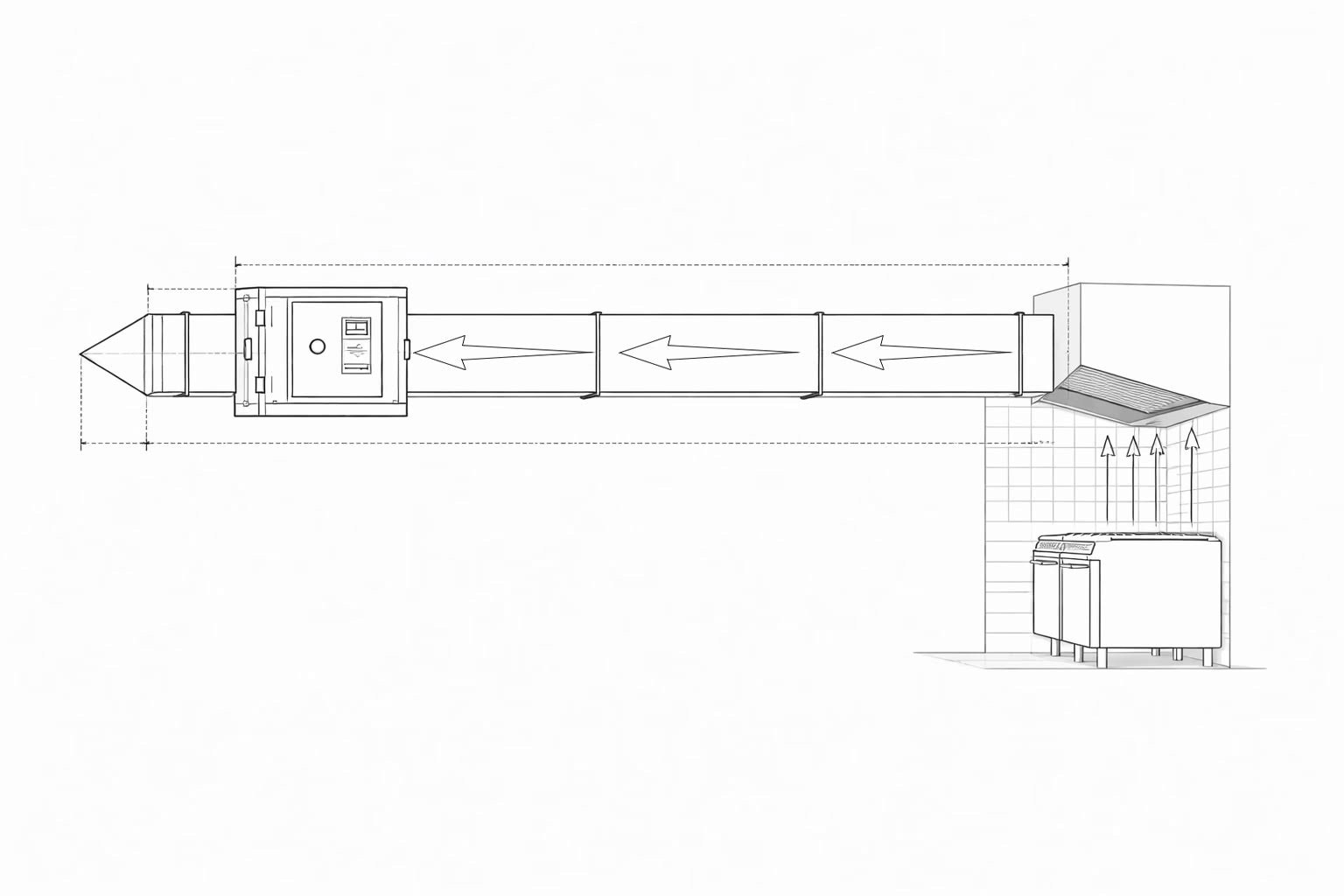

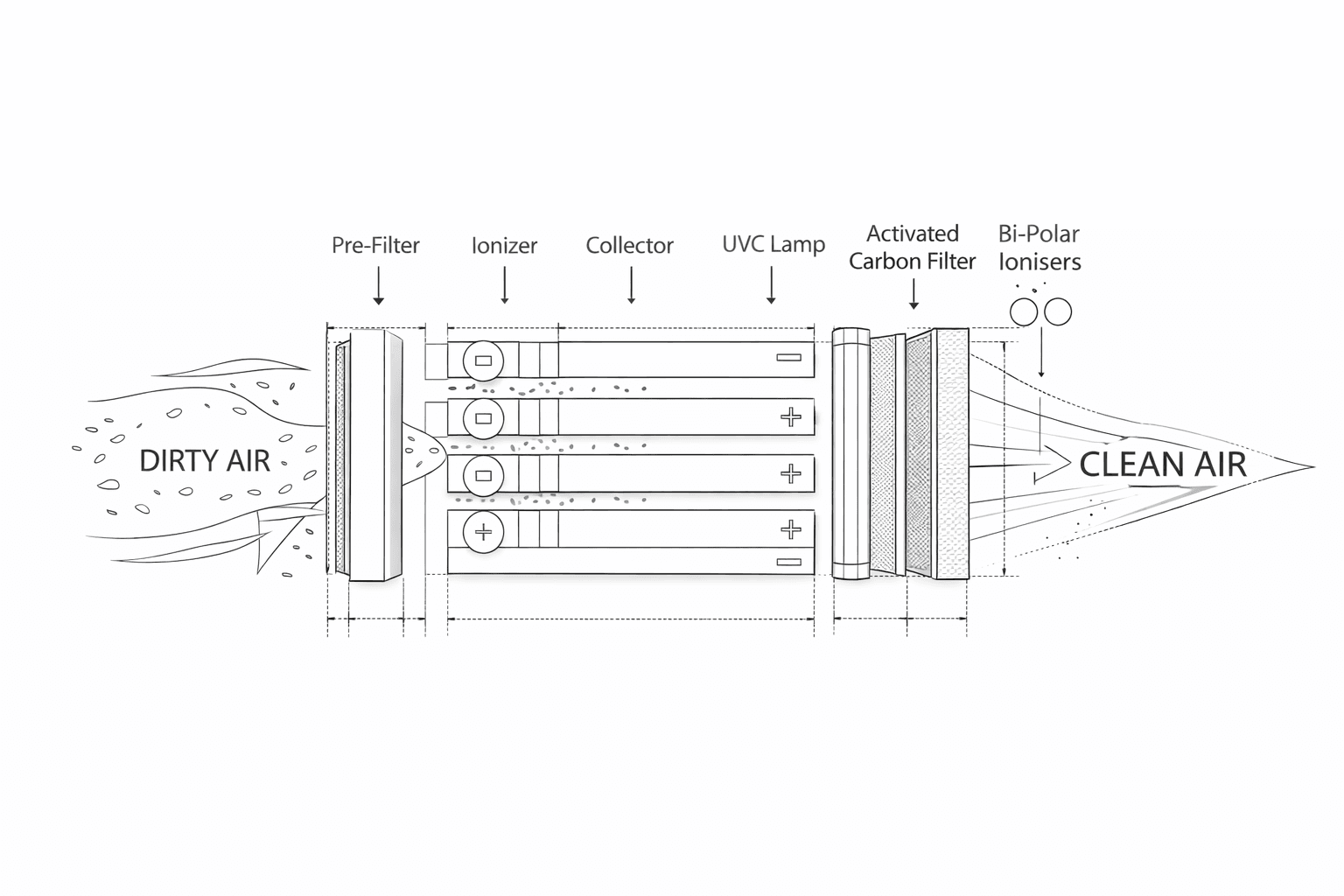

How it's works

Extract air passes through pre‑filtration before entering the electrostatic collection cells where grease and smoke particles are ionised and captured, delivering consistent filtration performance with low pressure loss.

RY7500B

- Notes

on

Application

Intended for high-demand commercial kitchens producing sustained grease and smoke loads.

Often used as the primary grease filtration stage in complex extraction systems.

Suitable for industrial process exhaust requiring efficient particulate removal.

Well suited to large plant rooms or centralised filtration systems.

Detailed Technical Information, Compliance & Performance Data

Industries We Design For

Each system is engineered around real-world airflow, contaminant and compliance requirements.