Trusted by Commercial & Industrial Leaders

Understanding System Performance in Real Applications

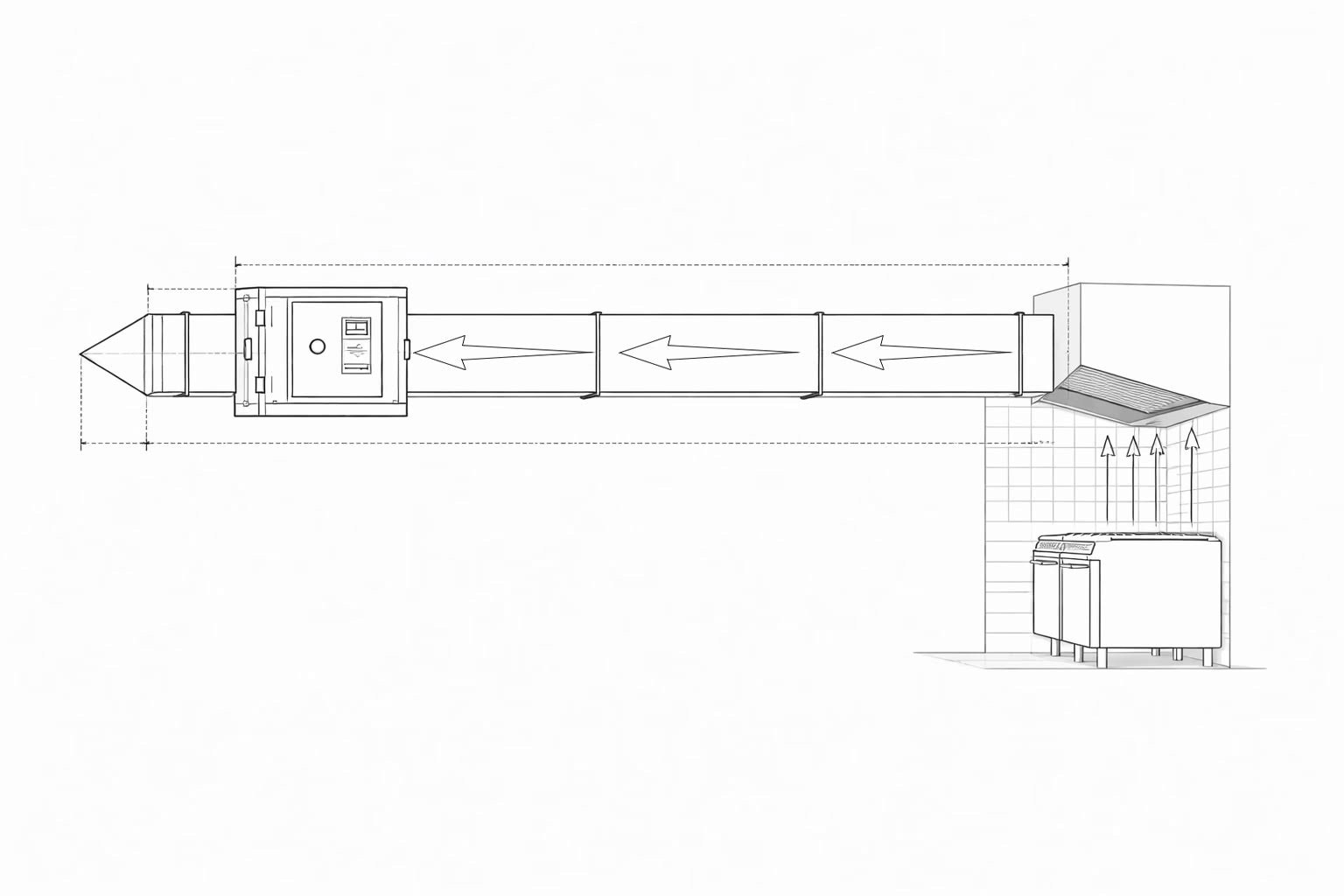

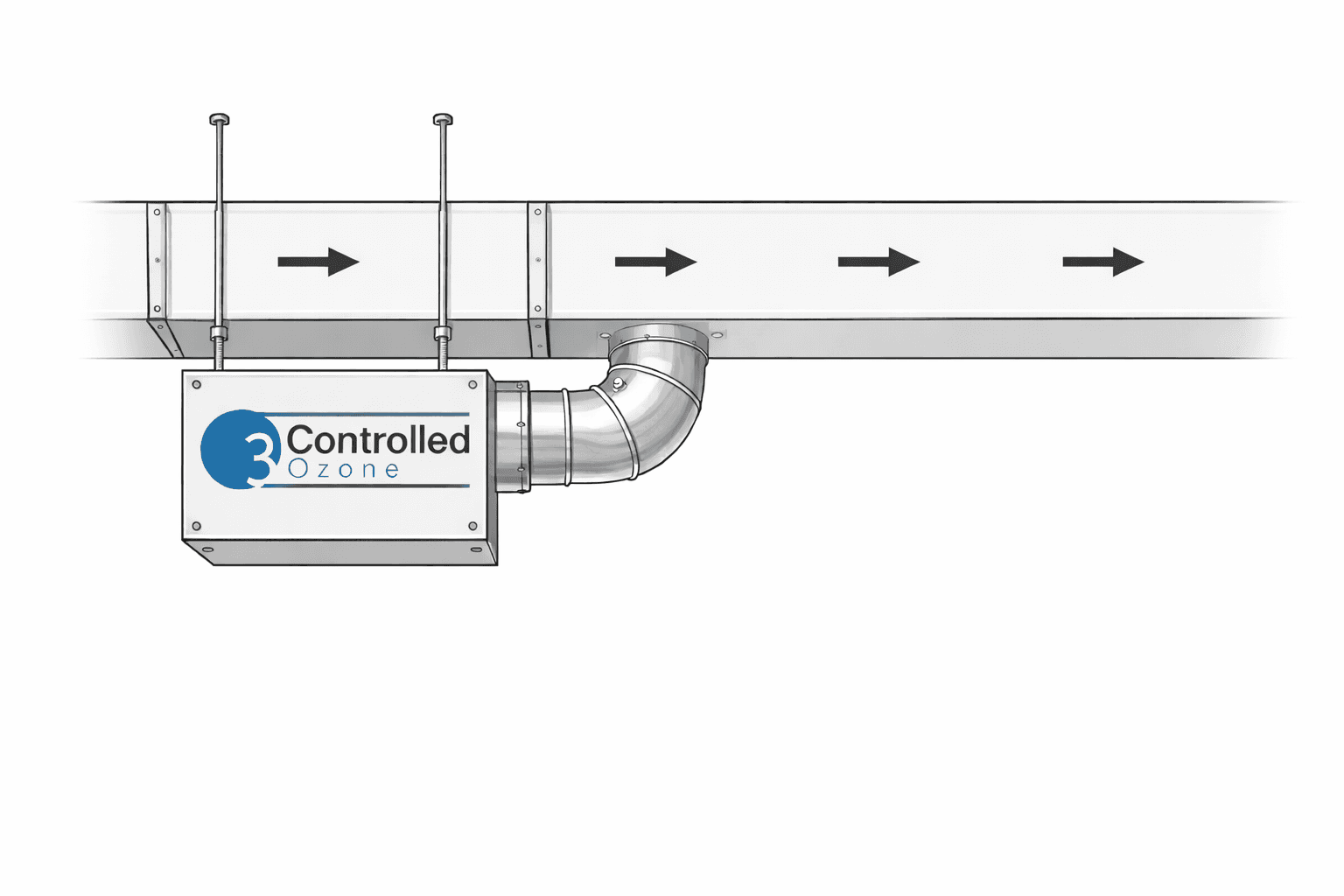

How it's works

Monitored ozone injection oxidises odour compounds within the duct while sensors regulate output to ensure compliance and safe operation at all times.

EXO400 Monitored Ozone System

- Notes

on

Application

Intended for large commercial kitchens and complex extraction systems with higher odour loads.

Suitable for high-capacity odour control in both kitchen and industrial environments.

Typically integrated with ESP, carbon, or UV systems as part of a multi-stage solution.

Ideal for installations requiring advanced monitoring and control.

Industries We Design For

Each system is engineered around real-world airflow, contaminant and compliance requirements.