Trusted by Commercial & Industrial Leaders

Understanding System Performance in Real Applications

How it's works

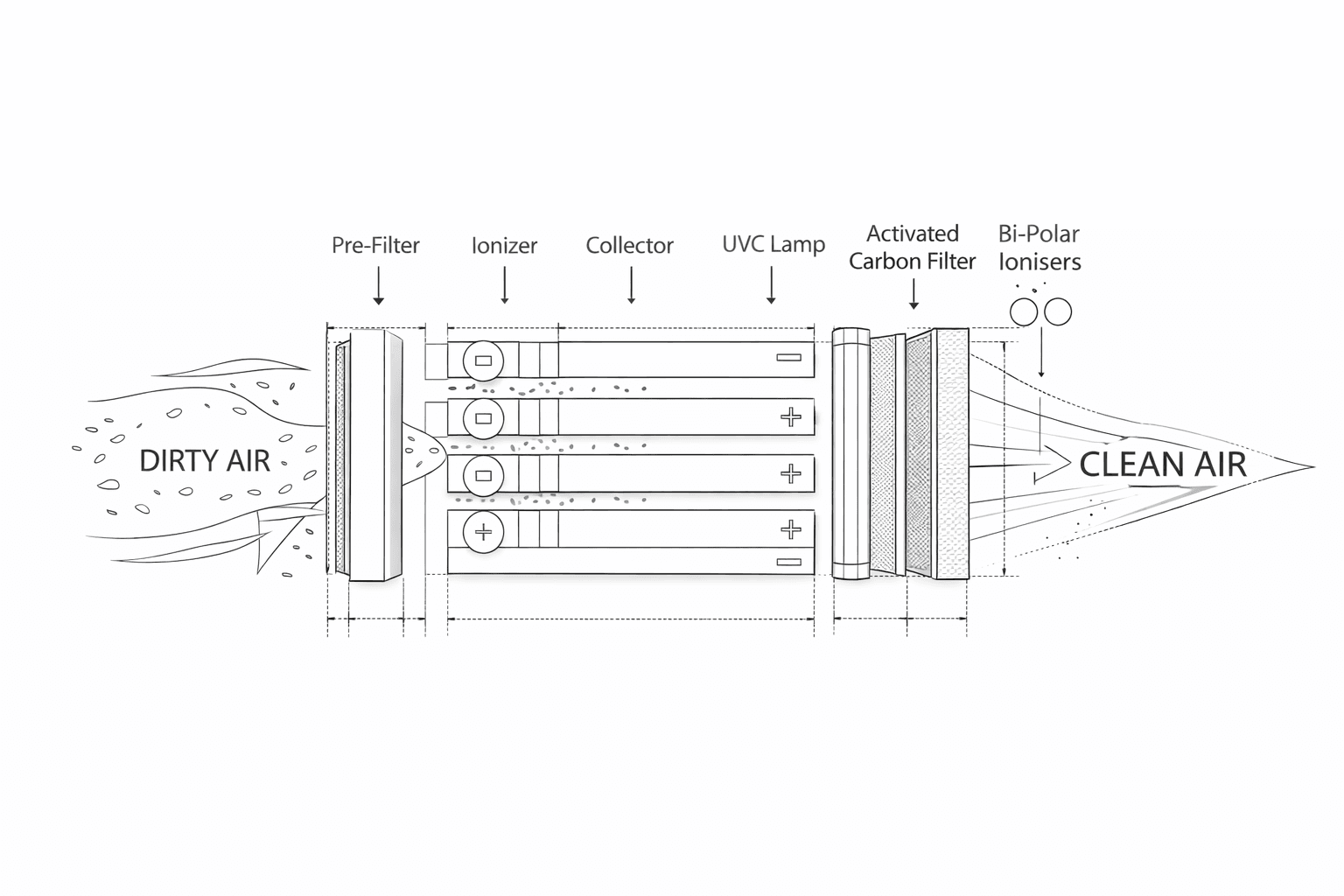

Air passes through the RY500B's washable pre‑filters before entering the electrostatic cells where smoke and grease particulates are electrically charged and collected on plates, allowing cleaner air to pass downstream with minimal pressure drop.

RY5000B

- Notes

on

Application

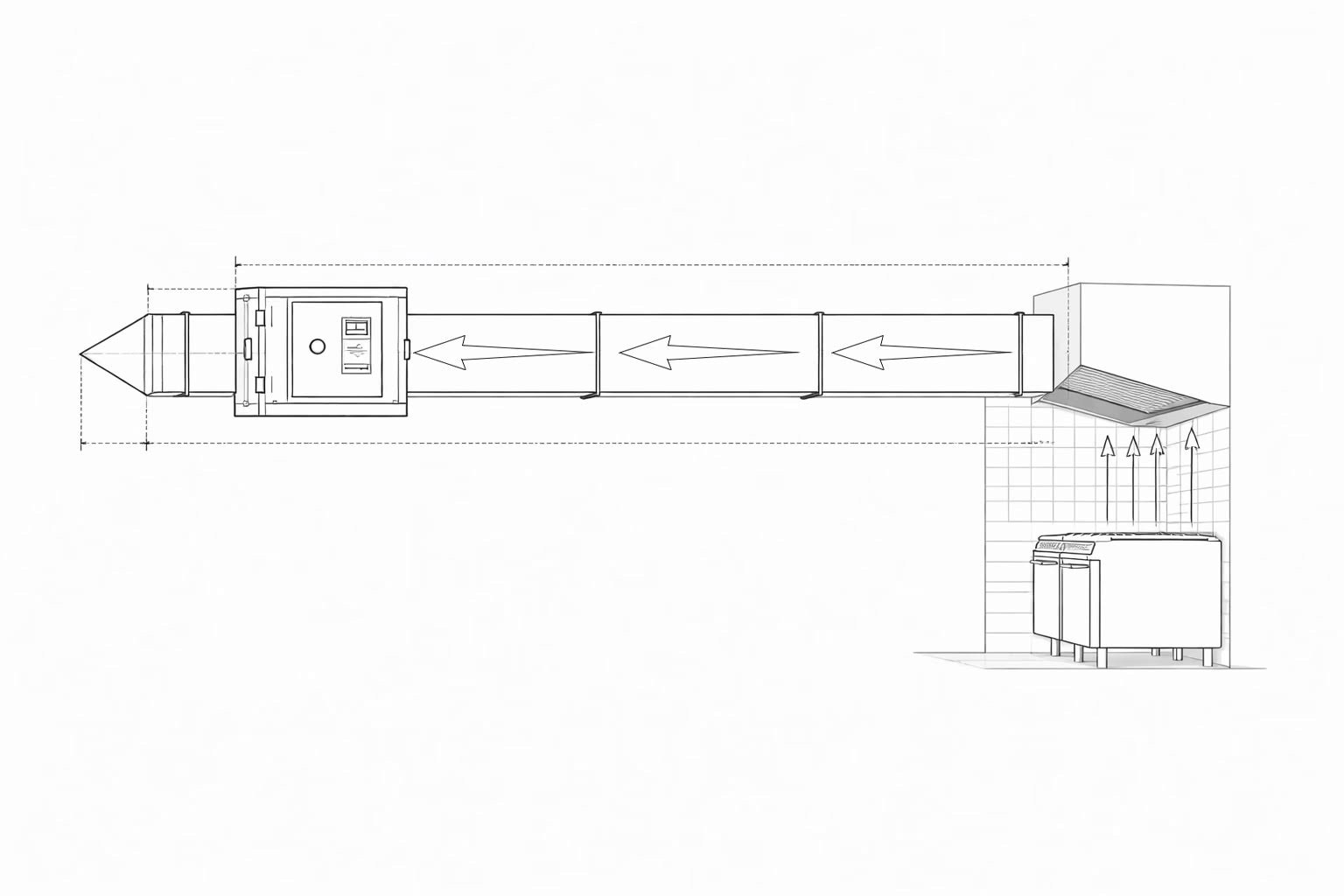

Designed for medium-capacity commercial kitchen extraction systems with higher cooking volumes.

Commonly specified as the main ESP stage ahead of secondary odour control systems.

Suitable for continuous-duty light industrial air filtration applications.

Appropriate for centralised plant installations serving multiple canopies.

Detailed Technical Information, Compliance & Performance Data

Industries We Design For

Each system is engineered around real-world airflow, contaminant and compliance requirements.