Trusted by Commercial & Industrial Leaders

Understanding System Performance in Real Applications

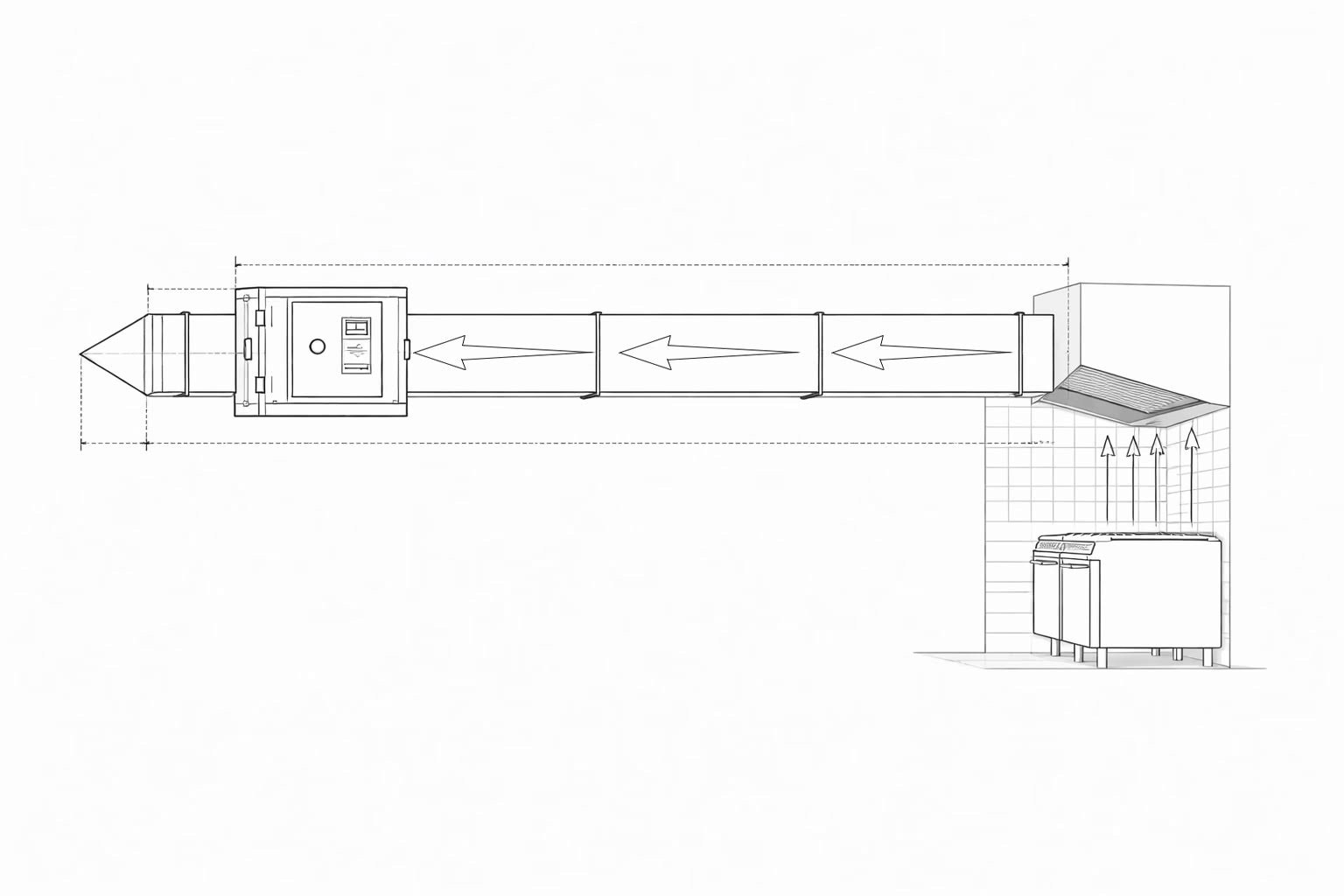

How it's works

Air passes through pleated media which increases surface area, capturing larger particles while maintaining consistent airflow.

Pleated Panel Filters

- Notes

on

Application

Used as primary pre-filters in kitchen and industrial ventilation systems.

Protects ESP, carbon, and HEPA stages by capturing larger particulates upstream.

Suitable for general air filtration applications where low resistance is required.

Available in standard sizes, with bespoke options available on request.

Industries We Design For

Each system is engineered around real-world airflow, contaminant and compliance requirements.