Trusted by Commercial & Industrial Leaders

Understanding System Performance in Real Applications

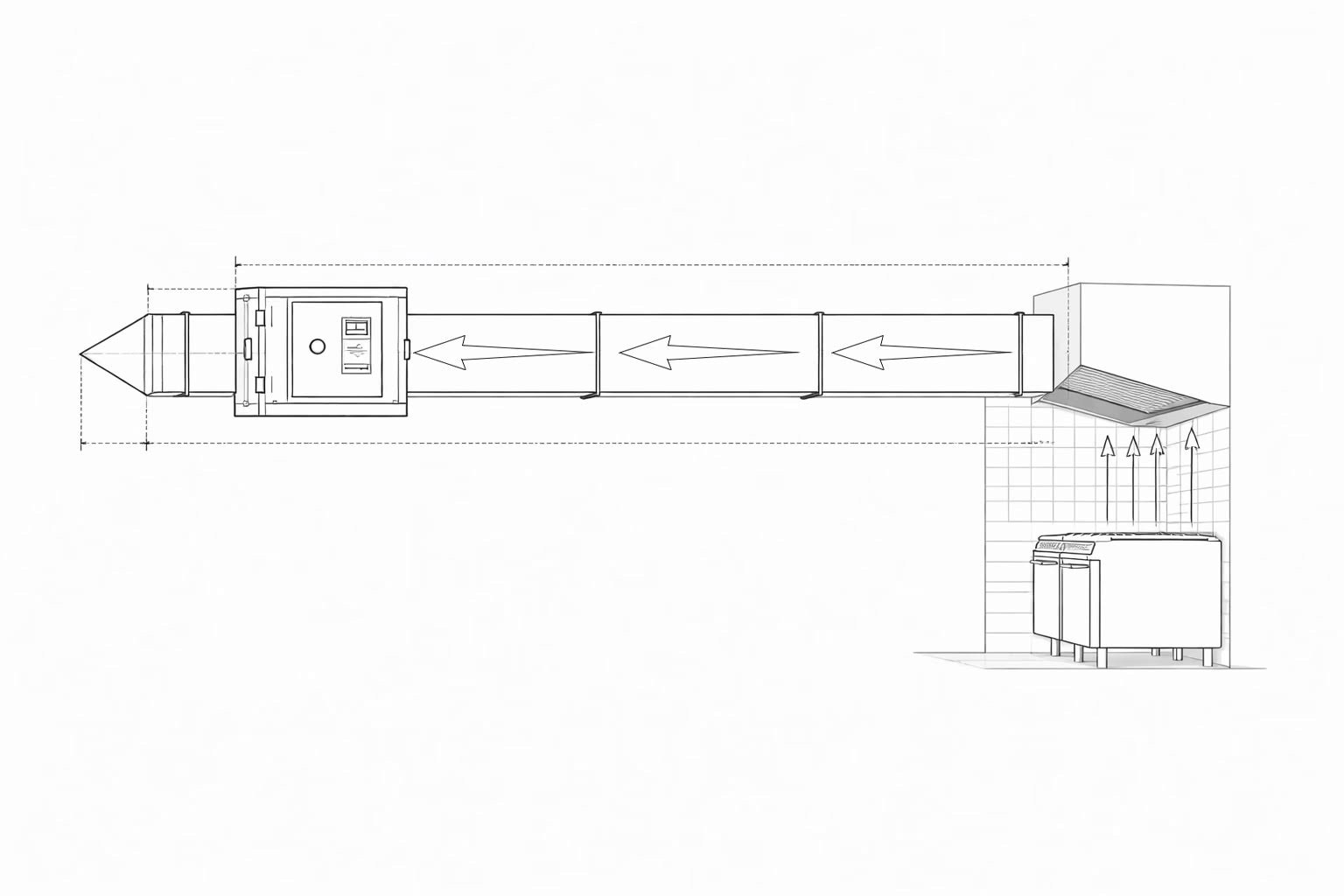

How it's works

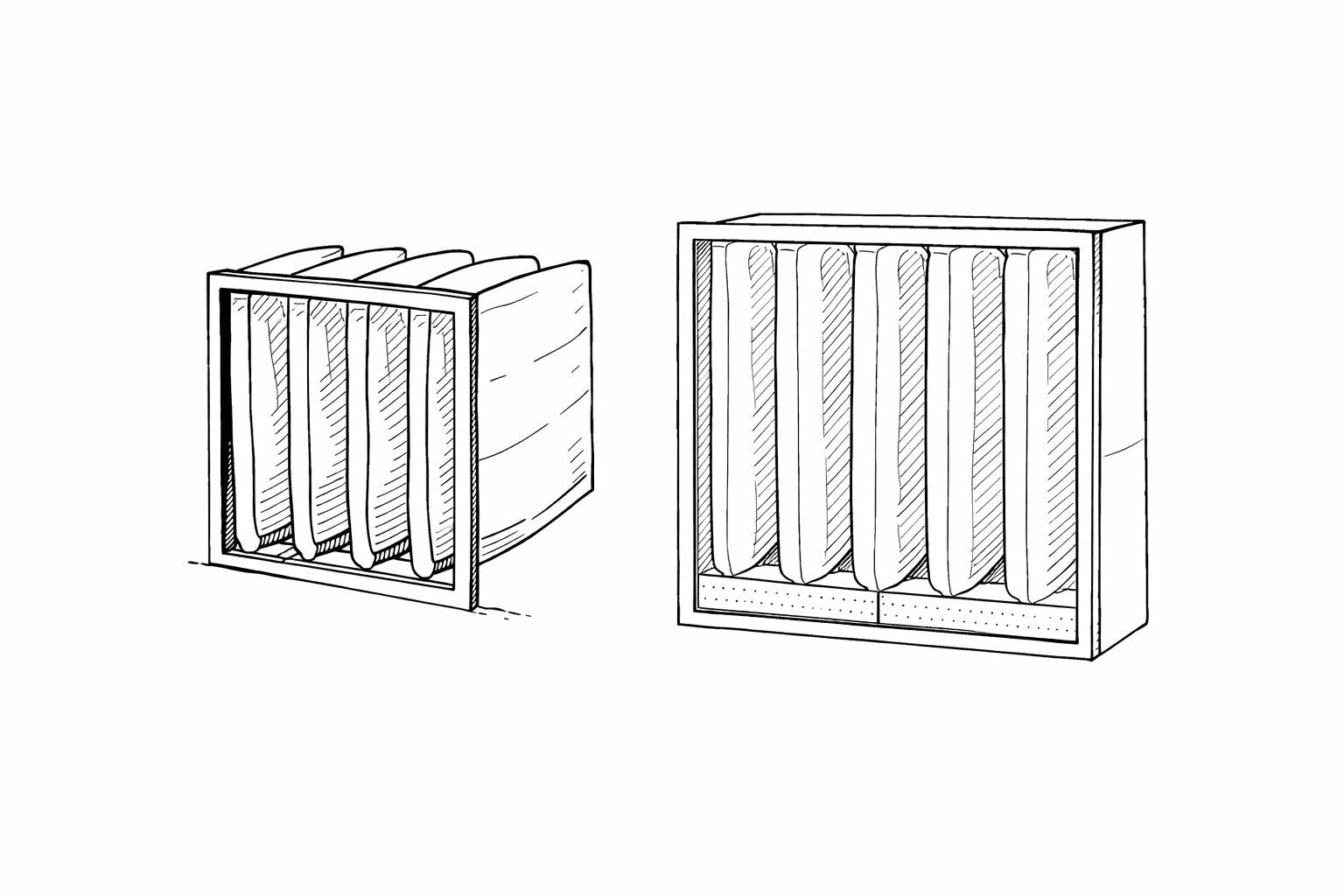

Air flows through multiple filter pockets which trap particulate while distributing airflow evenly to maximise dust holding capacity and service life.

Bag Filters

- Notes

on

Application

Commonly used as pre-filtration or intermediate filtration stages in air handling systems.

Suitable for commercial and industrial ventilation applications.

Helps protect downstream high-efficiency filters and sensitive equipment.

Installed in standard housings or modular filter units depending on system design.

Industries We Design For

Each system is engineered around real-world airflow, contaminant and compliance requirements.