Trusted by Commercial & Industrial Leaders

Understanding System Performance in Real Applications

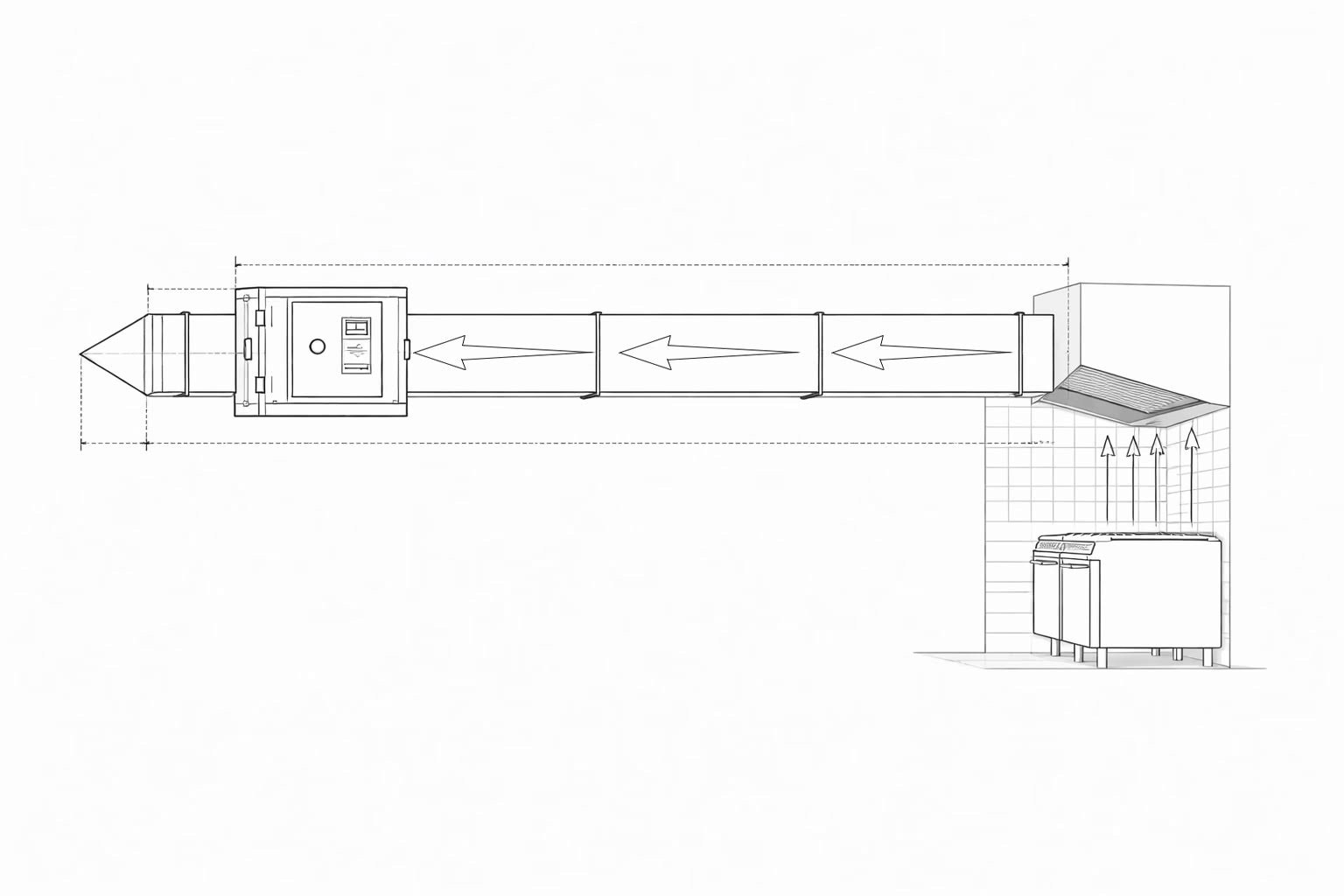

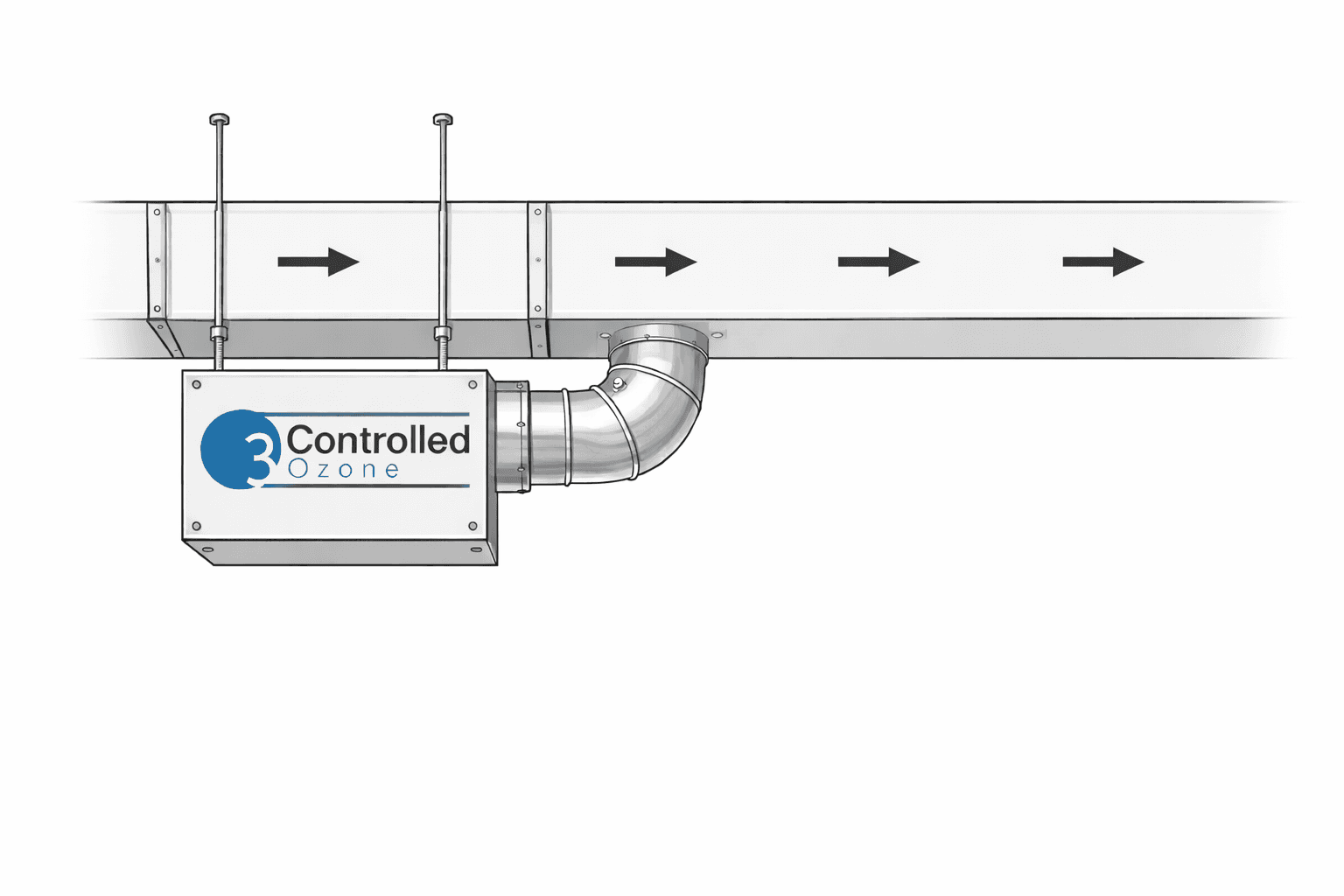

How it's works

Ozone is injected into the extract air and continuously monitored downstream, with output automatically adjusted to ensure effective odour control without exceeding safe limits.

EXO200 Monitored Ozone System

- Notes

on

Application

Designed for commercial kitchen systems requiring monitored ozone injection and controlled dosing.

Typically specified for sites with compliance, safety, or performance monitoring requirements.

Suitable for industrial air treatment applications requiring controlled ozone levels.

Often integrated into BMS-controlled ventilation systems.

Industries We Design For

Each system is engineered around real-world airflow, contaminant and compliance requirements.