Trusted by Commercial & Industrial Leaders

Understanding System Performance in Real Applications

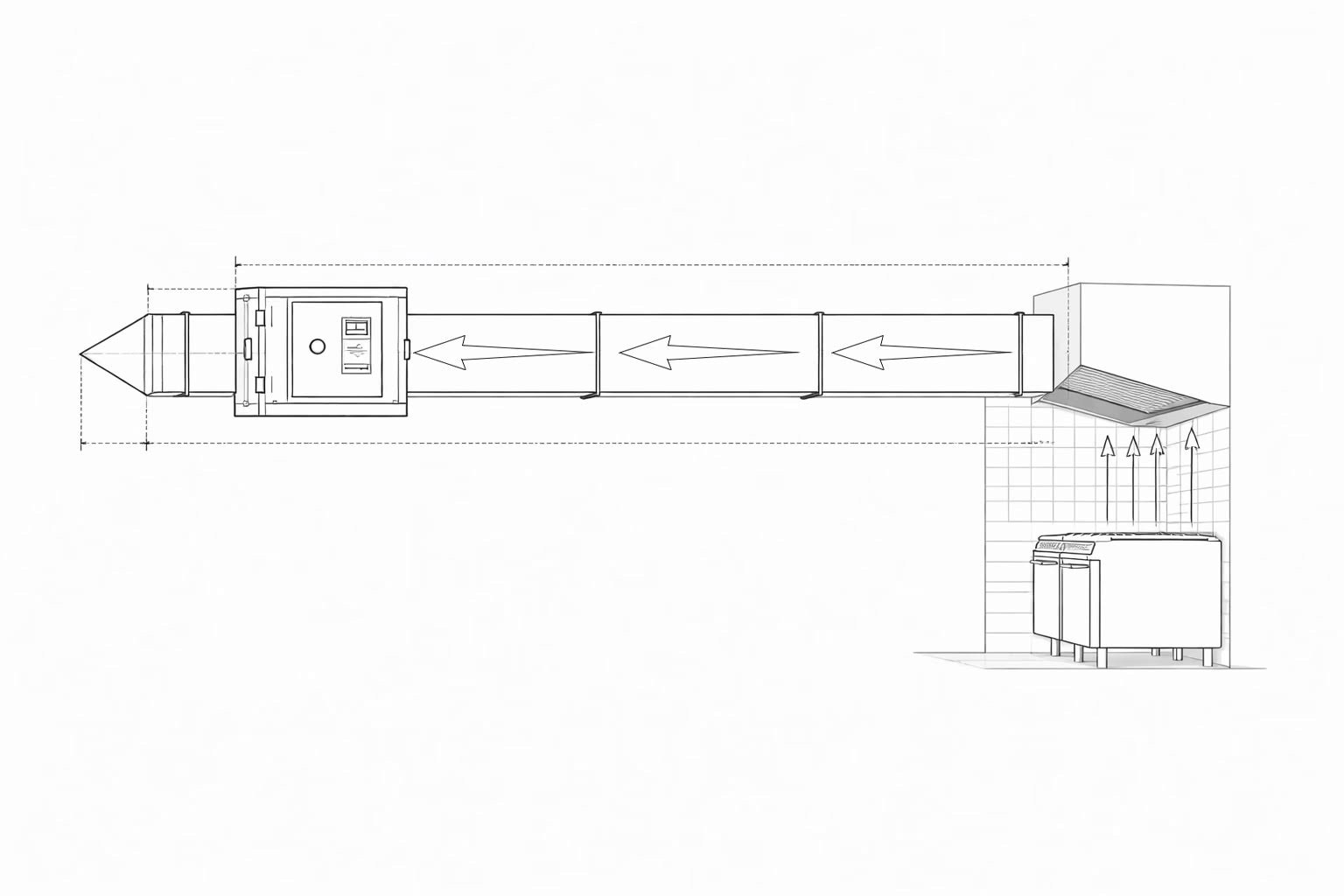

How it's works

Air passes through dense HEPA media where fine particulate is captured via diffusion and interception, delivering high-efficiency filtration before air is discharged or recirculated.

HEPA Filters

- Notes

on

Application

Used where high-efficiency particulate removal is required for sensitive environments.

Suitable for clean air applications, food production areas, and controlled ventilation systems.

Typically installed within dedicated housings or modular filter unit (MFU) systems.

Applied in both commercial and industrial air handling installations.

Industries We Design For

Each system is engineered around real-world airflow, contaminant and compliance requirements.