Trusted by Commercial & Industrial Leaders

Understanding System Performance in Real Applications

How it's works

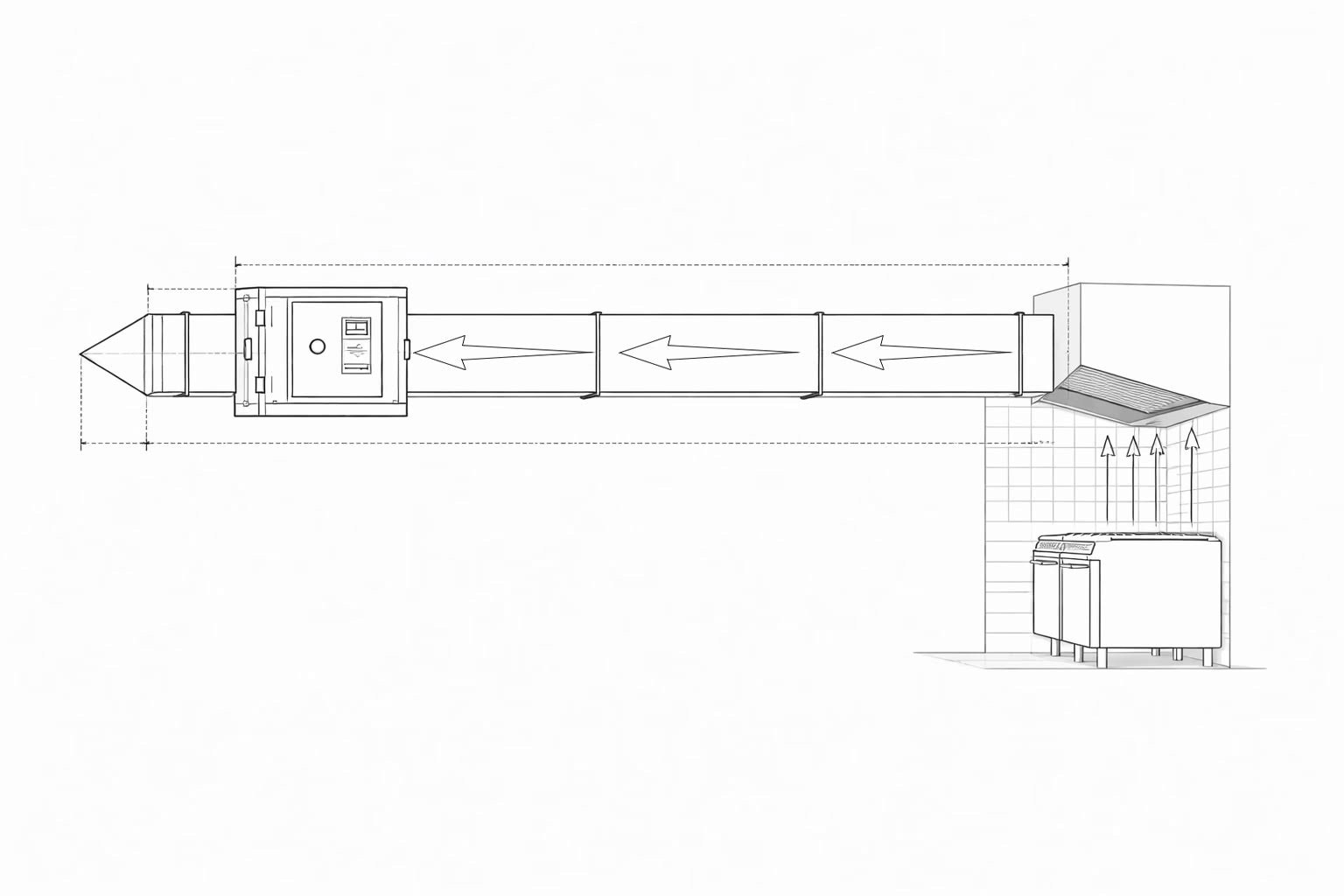

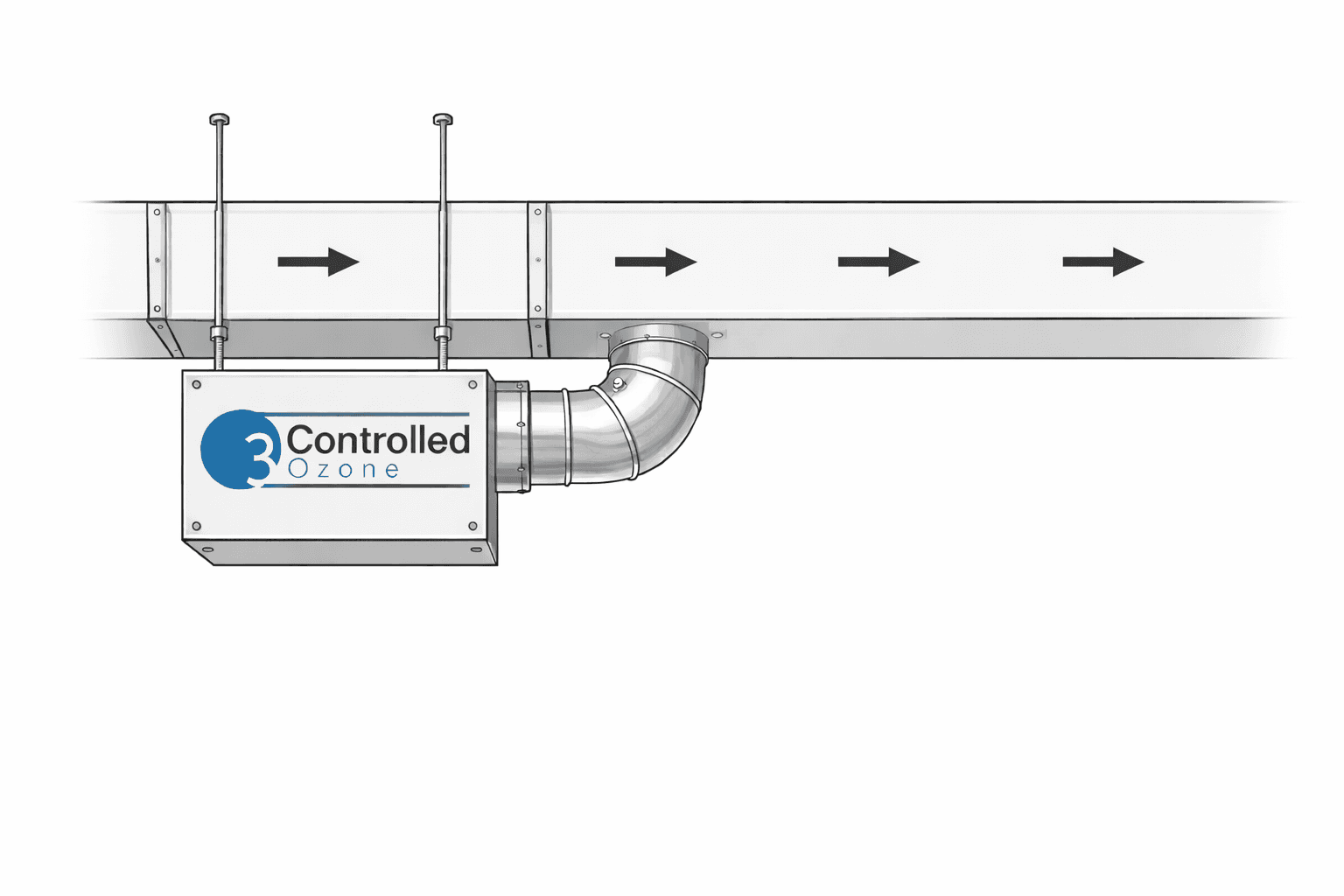

The system injects controlled ozone into the extract duct where it reacts with odorous compounds, with interlocks ensuring generation only occurs under safe airflow conditions.

EXO4 Controlled Ozone System

- Notes

on

Application

Applied in larger commercial kitchen extraction systems requiring higher ozone output.

Commonly installed downstream of ESP and/or carbon filtration stages.

Suitable for industrial odour control applications with moderate airflow rates.

Ideal where enhanced odour neutralisation is required.

Industries We Design For

Each system is engineered around real-world airflow, contaminant and compliance requirements.