Trusted by Commercial & Industrial Leaders

Understanding System Performance in Real Applications

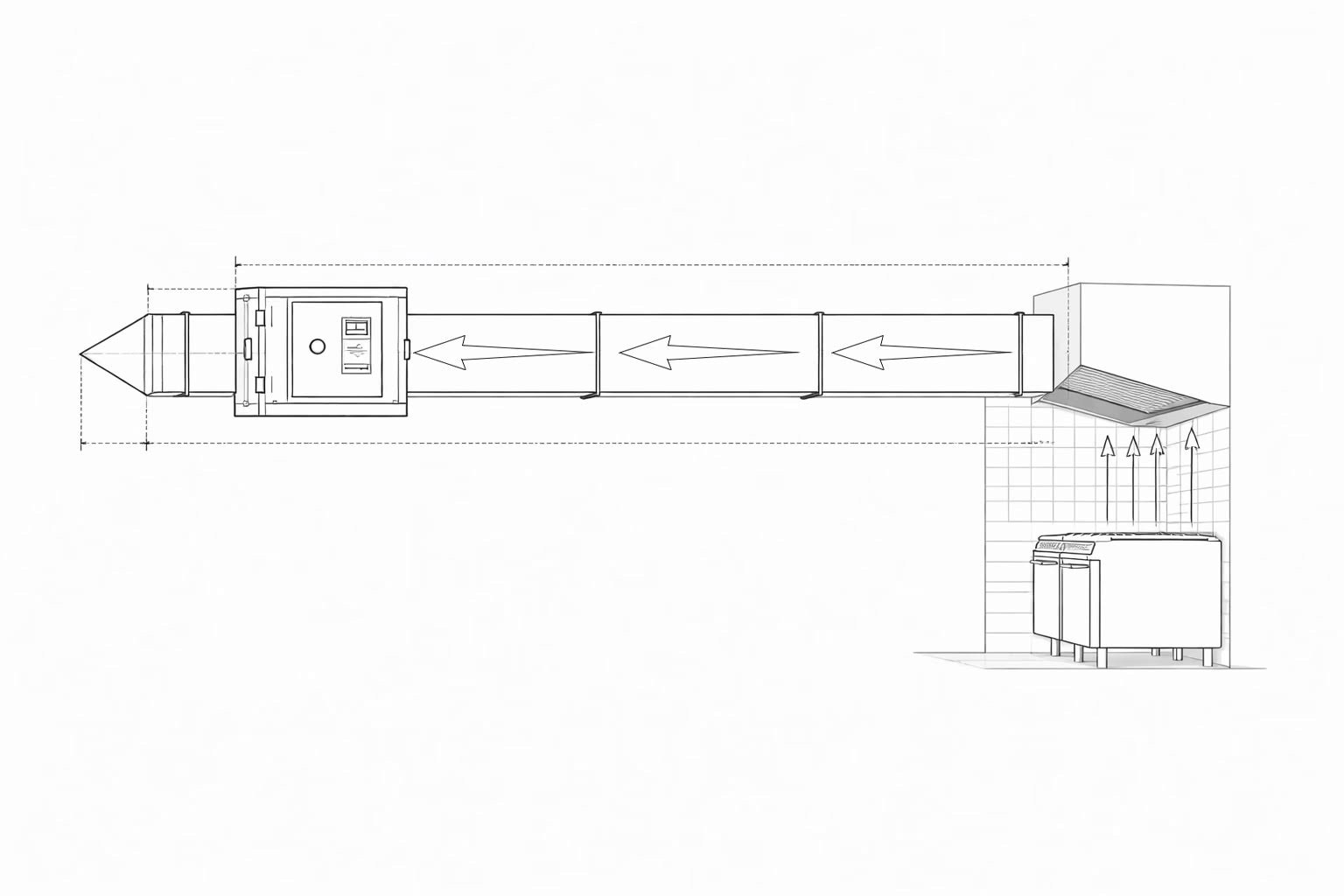

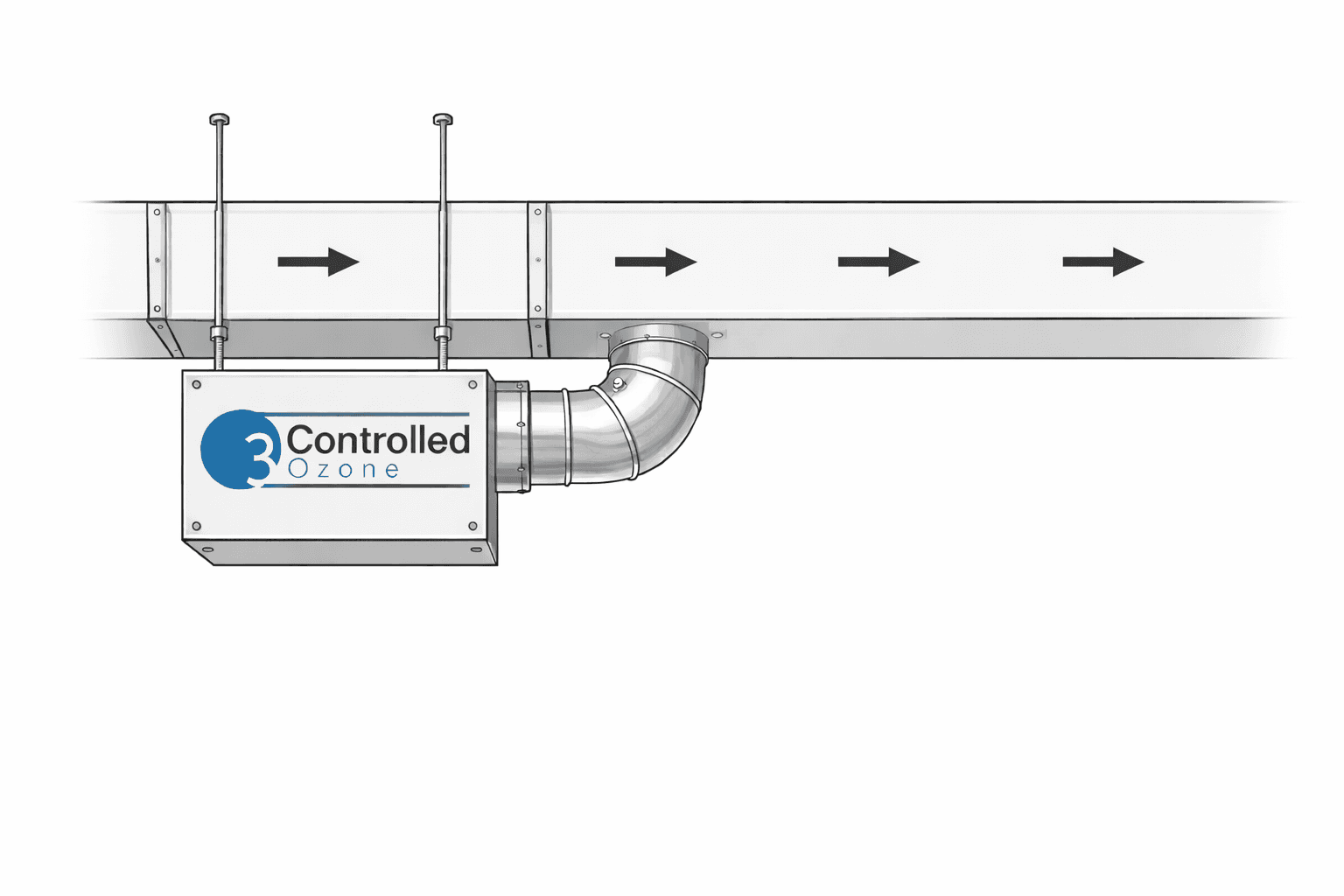

How it's works

Ozone is introduced into the extract air when airflow is present, reacting with odour molecules before discharge to atmosphere.

EXO20 Compact Ozone Injector

- Notes

on

Application

Designed for compact commercial kitchen extraction systems requiring controlled ozone injection.

Suitable for localised odour control applications where space is limited.

Typically installed downstream of grease and particulate filtration equipment.

Can be used in light industrial exhaust systems requiring targeted odour neutralisation.

Industries We Design For

Each system is engineered around real-world airflow, contaminant and compliance requirements.