Nov 18, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Dan Clarke

Technical Director, X Technology

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Nov 18, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Dan Clarke

Technical Director, X Technology

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Nov 18, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Dan Clarke

Technical Director, X Technology

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Hidden Costs of Poor Kitchen Ventilation in Restaurants

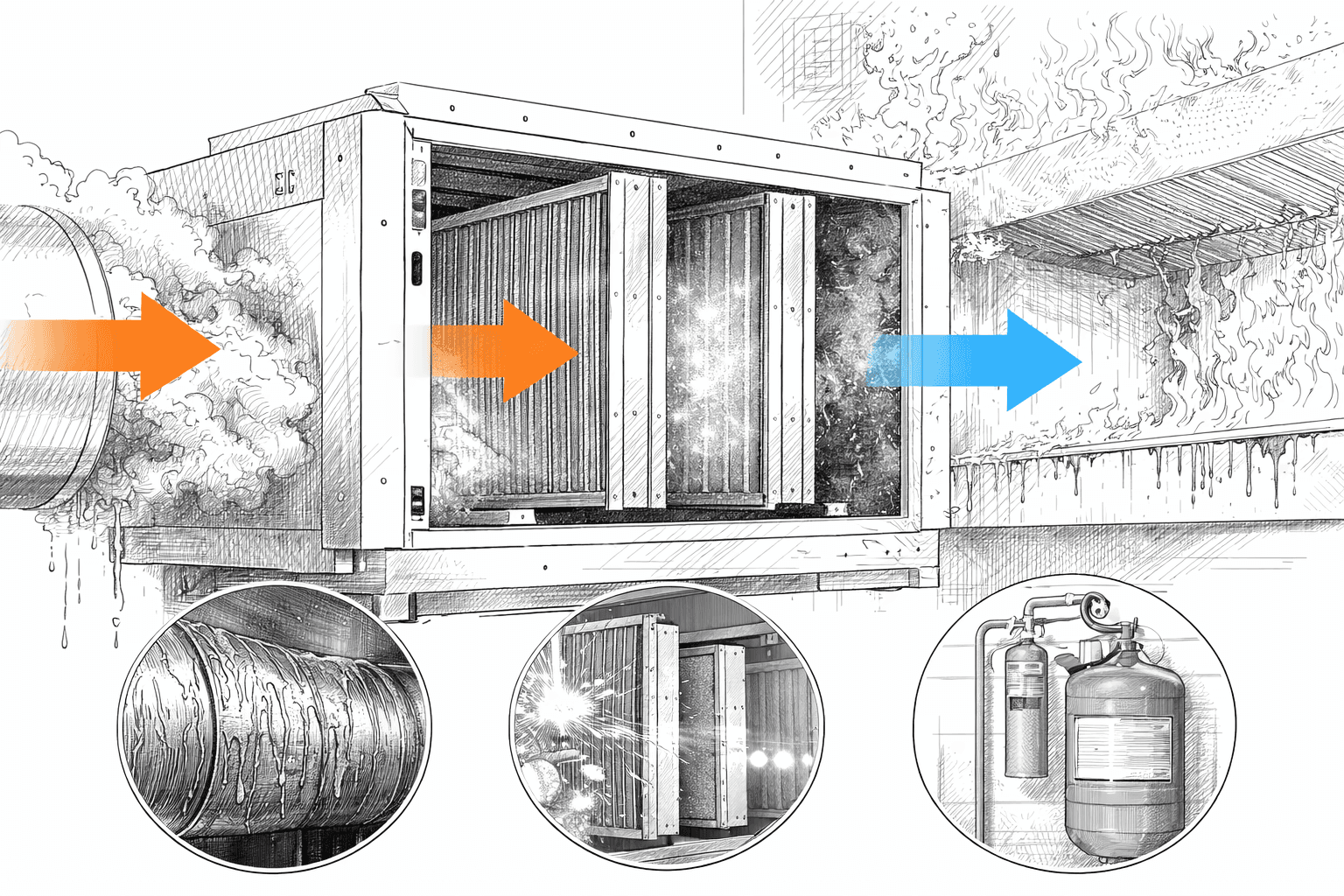

Behind every successful restaurant is a reliable extraction, ventilation and commercial kitchen filtration system. Its job is to remove grease, smoke, (with an ESP) and odour from the cooking process so that clean air is safely discharged to atmosphere in line with DW172 (<- click to read more)- the industry standard for commercial kitchen ventilation design.When ventilation systems are poorly designed, undersized, or neglected, the impact isn’t always immediate - but the hidden costs can quickly add up. From rising energy use to avoidable maintenance bills and enforcement notices, poor ventilation quietly erodes profitability, safety, and reputation.

Higher Energy and Maintenance Costs

When filters and ductwork become clogged with grease and smoke, fans must work harder to maintain extraction rates. This extra strain increases energy consumption, shortens fan lifespan, and adds unnecessary wear to motors and bearings.

Systems that are not balanced correctly or lack efficient particulate filtration - such as Electrostatic Precipitators (ESPs) - often operate noisily and unevenly, creating constant operational inefficiencies. Regular cleaning, correct airflow design, and proper filtration reduce energy waste and keep running costs predictable.

Fire Hazards and Insurance Implications

Grease deposits inside extract ducts are a leading cause of commercial kitchen fires. Inadequate filtration allows grease to accumulate, increasing the risk of ignition and rapid fire spread through ductwork.Insurers and local authorities expect systems to meet the performance and maintenance recommendations set out in DW/172 and TR/19 (for duct cleaning). Non-compliance can lead to higher premiums or even the invalidation of insurance cover.A well-maintained filtration system - including ESPs, UV-O units, and accessible duct sections - dramatically reduces fire risk and satisfies insurer requirements.

Odour Complaints and Environmental Enforcement

Cooking odours escaping into nearby properties or public areas are one of the most common reasons for complaints to Environmental Health Officers (EHOs). In urban or mixed-use locations, repeated issues can lead to enforcement notices or restrictions on trading hours.

A modern odour-control solution combines UV-O systems (to break down volatile organic compounds) with activated carbon filters that adsorb residual smells. Together, they ensure clean, neutral air discharge and help operators stay in line with planning conditions.

Preventing odour complaints not only keeps neighbours happy - it safeguards your licence and reputation.

Staff Comfort, Hygiene, and Productivity

Poor ventilation affects air quality inside the kitchen as well as outside. Without adequate extraction, fine grease mist can settle on surfaces and equipment, creating extra cleaning demands and hygiene risks.

A clean airflow path supported by efficient filtration improves working conditions, reduces airborne contaminants, and helps maintain compliance during hygiene inspections. Comfortable, well-ventilated kitchens also support better staff morale and retention - an often-overlooked benefit.

Equipment Downtime and Operational Disruption

Blocked filters or overloaded fans frequently cause unscheduled breakdowns. A failed extract system can bring cooking operations to a standstill - costing both revenue and customer confidence.Regular maintenance - including washing ESP cells, replacing UV lamps, and monitoring carbon filter performance - keeps systems reliable and prevents expensive call-outs or downtime during service.

Long-Term Financial Impact

Restaurants that neglect their extraction systems often find themselves trapped in a cycle of reactive maintenance and repeated complaints. Over time, the cumulative cost of energy waste, repairs, and enforcement can exceed the investment in a properly specified, DW/172-compliant system.A proactive approach - with efficient filtration, scheduled servicing, and clear documentation - protects profitability and ensures your kitchen continues to operate safely and efficiently. Poor kitchen ventilation doesn’t just cause smoke and odour - it quietly increases energy bills, raises fire risk, and damages reputation. A well-designed, properly maintained system is a long-term investment that keeps restaurants compliant, efficient, and worry-free.

By partnering with an experienced manufacturer such as Extechnology, operators can ensure their extraction and filtration systems meet DW/172 standards, minimise risk, and deliver clean, odour-free air year-round.

For more technical information and maintenance advice, visit our Extechnology Blog.To explore our full range of DW/172-compliant ESP, UV-O, and carbon filtration systems, browse our products here.

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Behind every successful restaurant is a reliable extraction, ventilation and commercial kitchen filtration system. Its job is to remove grease, smoke, (with an ESP) and odour from the cooking process so that clean air is safely discharged to atmosphere in line with DW172 (<- click to read more)- the industry standard for commercial kitchen ventilation design.When ventilation systems are poorly designed, undersized, or neglected, the impact isn’t always immediate - but the hidden costs can quickly add up. From rising energy use to avoidable maintenance bills and enforcement notices, poor ventilation quietly erodes profitability, safety, and reputation.

Higher Energy and Maintenance Costs

When filters and ductwork become clogged with grease and smoke, fans must work harder to maintain extraction rates. This extra strain increases energy consumption, shortens fan lifespan, and adds unnecessary wear to motors and bearings.

Systems that are not balanced correctly or lack efficient particulate filtration - such as Electrostatic Precipitators (ESPs) - often operate noisily and unevenly, creating constant operational inefficiencies. Regular cleaning, correct airflow design, and proper filtration reduce energy waste and keep running costs predictable.

Fire Hazards and Insurance Implications

Grease deposits inside extract ducts are a leading cause of commercial kitchen fires. Inadequate filtration allows grease to accumulate, increasing the risk of ignition and rapid fire spread through ductwork.Insurers and local authorities expect systems to meet the performance and maintenance recommendations set out in DW/172 and TR/19 (for duct cleaning). Non-compliance can lead to higher premiums or even the invalidation of insurance cover.A well-maintained filtration system - including ESPs, UV-O units, and accessible duct sections - dramatically reduces fire risk and satisfies insurer requirements.

Odour Complaints and Environmental Enforcement

Cooking odours escaping into nearby properties or public areas are one of the most common reasons for complaints to Environmental Health Officers (EHOs). In urban or mixed-use locations, repeated issues can lead to enforcement notices or restrictions on trading hours.

A modern odour-control solution combines UV-O systems (to break down volatile organic compounds) with activated carbon filters that adsorb residual smells. Together, they ensure clean, neutral air discharge and help operators stay in line with planning conditions.

Preventing odour complaints not only keeps neighbours happy - it safeguards your licence and reputation.

Staff Comfort, Hygiene, and Productivity

Poor ventilation affects air quality inside the kitchen as well as outside. Without adequate extraction, fine grease mist can settle on surfaces and equipment, creating extra cleaning demands and hygiene risks.

A clean airflow path supported by efficient filtration improves working conditions, reduces airborne contaminants, and helps maintain compliance during hygiene inspections. Comfortable, well-ventilated kitchens also support better staff morale and retention - an often-overlooked benefit.

Equipment Downtime and Operational Disruption

Blocked filters or overloaded fans frequently cause unscheduled breakdowns. A failed extract system can bring cooking operations to a standstill - costing both revenue and customer confidence.Regular maintenance - including washing ESP cells, replacing UV lamps, and monitoring carbon filter performance - keeps systems reliable and prevents expensive call-outs or downtime during service.

Long-Term Financial Impact

Restaurants that neglect their extraction systems often find themselves trapped in a cycle of reactive maintenance and repeated complaints. Over time, the cumulative cost of energy waste, repairs, and enforcement can exceed the investment in a properly specified, DW/172-compliant system.A proactive approach - with efficient filtration, scheduled servicing, and clear documentation - protects profitability and ensures your kitchen continues to operate safely and efficiently. Poor kitchen ventilation doesn’t just cause smoke and odour - it quietly increases energy bills, raises fire risk, and damages reputation. A well-designed, properly maintained system is a long-term investment that keeps restaurants compliant, efficient, and worry-free.

By partnering with an experienced manufacturer such as Extechnology, operators can ensure their extraction and filtration systems meet DW/172 standards, minimise risk, and deliver clean, odour-free air year-round.

For more technical information and maintenance advice, visit our Extechnology Blog.To explore our full range of DW/172-compliant ESP, UV-O, and carbon filtration systems, browse our products here.

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Behind every successful restaurant is a reliable extraction, ventilation and commercial kitchen filtration system. Its job is to remove grease, smoke, (with an ESP) and odour from the cooking process so that clean air is safely discharged to atmosphere in line with DW172 (<- click to read more)- the industry standard for commercial kitchen ventilation design.When ventilation systems are poorly designed, undersized, or neglected, the impact isn’t always immediate - but the hidden costs can quickly add up. From rising energy use to avoidable maintenance bills and enforcement notices, poor ventilation quietly erodes profitability, safety, and reputation.

Higher Energy and Maintenance Costs

When filters and ductwork become clogged with grease and smoke, fans must work harder to maintain extraction rates. This extra strain increases energy consumption, shortens fan lifespan, and adds unnecessary wear to motors and bearings.

Systems that are not balanced correctly or lack efficient particulate filtration - such as Electrostatic Precipitators (ESPs) - often operate noisily and unevenly, creating constant operational inefficiencies. Regular cleaning, correct airflow design, and proper filtration reduce energy waste and keep running costs predictable.

Fire Hazards and Insurance Implications

Grease deposits inside extract ducts are a leading cause of commercial kitchen fires. Inadequate filtration allows grease to accumulate, increasing the risk of ignition and rapid fire spread through ductwork.Insurers and local authorities expect systems to meet the performance and maintenance recommendations set out in DW/172 and TR/19 (for duct cleaning). Non-compliance can lead to higher premiums or even the invalidation of insurance cover.A well-maintained filtration system - including ESPs, UV-O units, and accessible duct sections - dramatically reduces fire risk and satisfies insurer requirements.

Odour Complaints and Environmental Enforcement

Cooking odours escaping into nearby properties or public areas are one of the most common reasons for complaints to Environmental Health Officers (EHOs). In urban or mixed-use locations, repeated issues can lead to enforcement notices or restrictions on trading hours.

A modern odour-control solution combines UV-O systems (to break down volatile organic compounds) with activated carbon filters that adsorb residual smells. Together, they ensure clean, neutral air discharge and help operators stay in line with planning conditions.

Preventing odour complaints not only keeps neighbours happy - it safeguards your licence and reputation.

Staff Comfort, Hygiene, and Productivity

Poor ventilation affects air quality inside the kitchen as well as outside. Without adequate extraction, fine grease mist can settle on surfaces and equipment, creating extra cleaning demands and hygiene risks.

A clean airflow path supported by efficient filtration improves working conditions, reduces airborne contaminants, and helps maintain compliance during hygiene inspections. Comfortable, well-ventilated kitchens also support better staff morale and retention - an often-overlooked benefit.

Equipment Downtime and Operational Disruption

Blocked filters or overloaded fans frequently cause unscheduled breakdowns. A failed extract system can bring cooking operations to a standstill - costing both revenue and customer confidence.Regular maintenance - including washing ESP cells, replacing UV lamps, and monitoring carbon filter performance - keeps systems reliable and prevents expensive call-outs or downtime during service.

Long-Term Financial Impact

Restaurants that neglect their extraction systems often find themselves trapped in a cycle of reactive maintenance and repeated complaints. Over time, the cumulative cost of energy waste, repairs, and enforcement can exceed the investment in a properly specified, DW/172-compliant system.A proactive approach - with efficient filtration, scheduled servicing, and clear documentation - protects profitability and ensures your kitchen continues to operate safely and efficiently. Poor kitchen ventilation doesn’t just cause smoke and odour - it quietly increases energy bills, raises fire risk, and damages reputation. A well-designed, properly maintained system is a long-term investment that keeps restaurants compliant, efficient, and worry-free.

By partnering with an experienced manufacturer such as Extechnology, operators can ensure their extraction and filtration systems meet DW/172 standards, minimise risk, and deliver clean, odour-free air year-round.

For more technical information and maintenance advice, visit our Extechnology Blog.To explore our full range of DW/172-compliant ESP, UV-O, and carbon filtration systems, browse our products here.

Call Us Now

London Office Address:

London Phone Number:

Email Address:

Call Us Now

London Phone Number:

Email Address:

Call Us Now

London Office Address:

London Phone Number:

Email Address: