Odour Control

15 Feb 2026

Odour Control Carbon Filters in Commercial Kitchens

Carbon filters are one of the most widely specified odour control solutions in restaurant kitchens — and also one of the most misunderstood.

Carbon filters are one of the most widely specified odour control solutions in restaurant kitchens — and also one of the most misunderstood. When applied correctly, they are highly effective at polishing kitchen extract air. When applied incorrectly, they become expensive, short-lived, and a common cause of ongoing odour complaints.

What Carbon Filters Actually Do

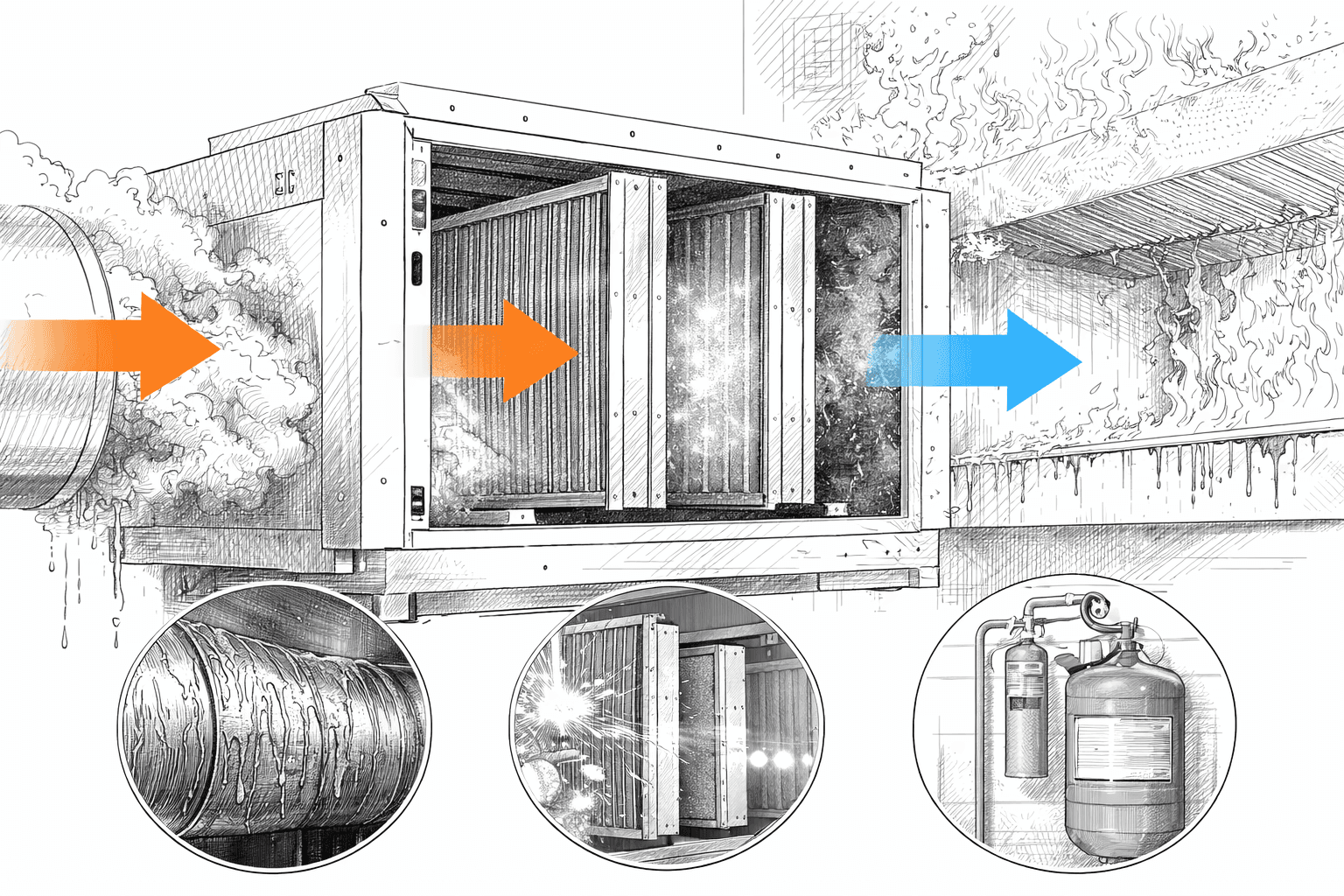

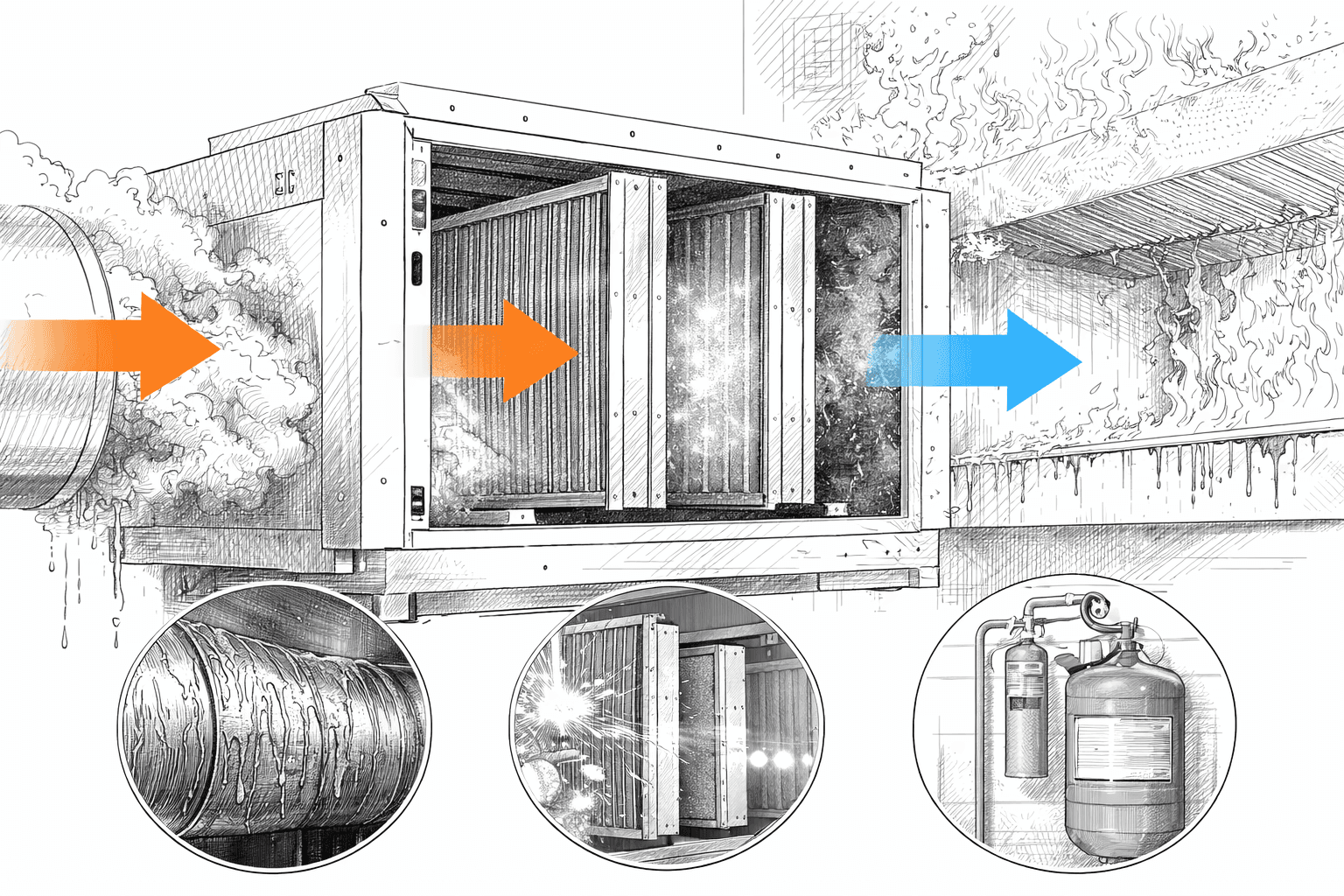

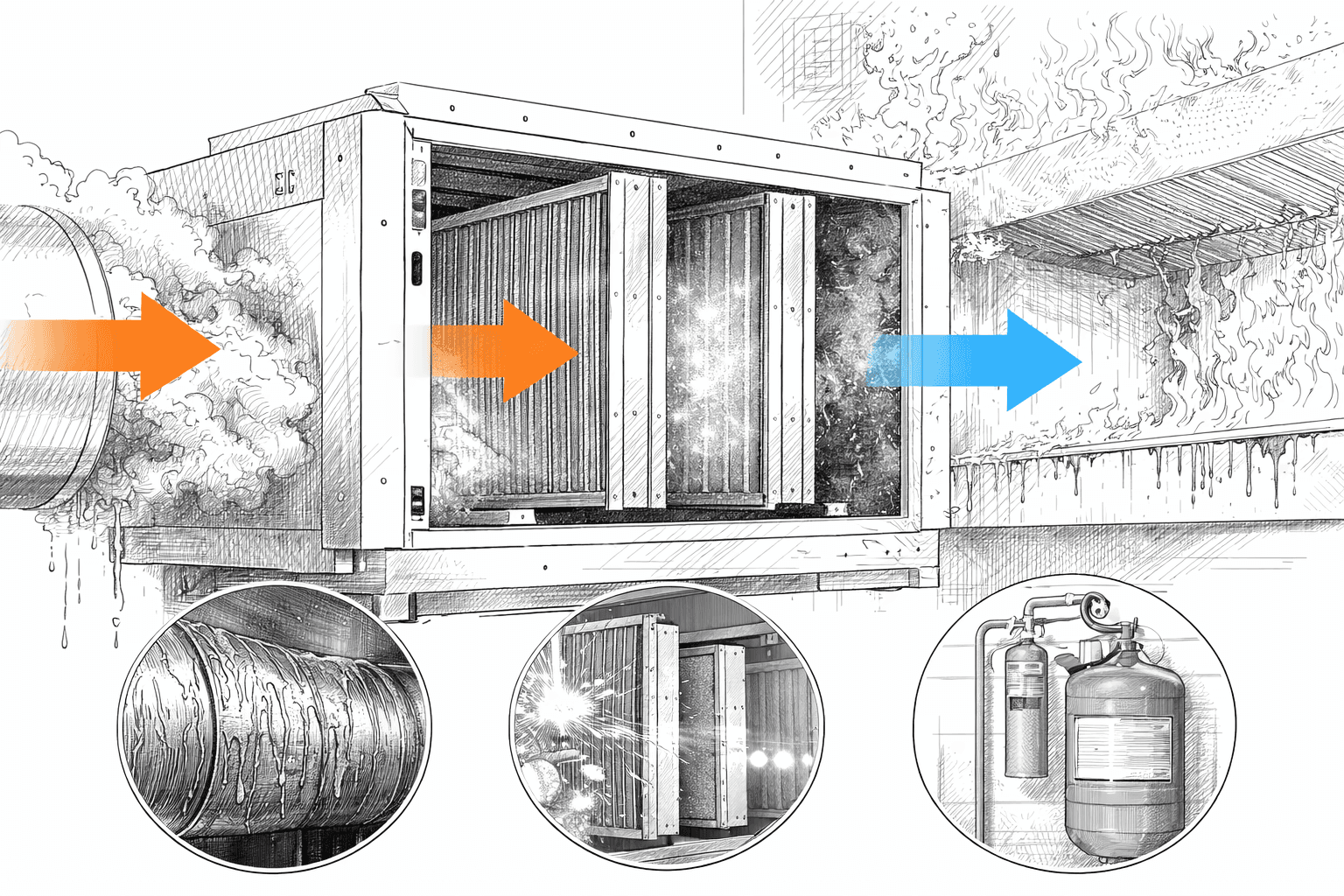

Activated carbon works by adsorbing odorous gases and volatile organic compounds (VOCs) from kitchen extract air. Unlike grease filters or ESPs, carbon does not remove smoke or particulates - it deals purely with odour at a molecular level.

In a commercial kitchen context, carbon filters are typically used as the final stage in an odour control system, once grease and smoke have already been removed upstream.

Carbon is not a primary treatment. It is a finishing process.

Why Carbon Alone Is Not Enough

One of the most common design errors in restaurant kitchens is relying on carbon filters as the only form of treatment.

If grease, oil mist, and smoke reach the carbon bed:

Carbon pores become blocked rapidly

Odour removal efficiency drops sharply

Breakthrough occurs far earlier than expected

This leads to the perception that “carbon doesn’t work”, when in reality the issue is upstream filtration.

For carbon to perform properly in commercial kitchens, it must be protected by:

Effective grease filtration at the canopy

High-efficiency particulate removal, typically via ESP

Carbon Filter Design Considerations

Carbon performance in restaurant kitchens is driven by dwell time, not just carbon weight.

Key factors that must be designed correctly:

Face velocity: Air must pass slowly enough through the carbon for adsorption to occur

Bed depth: Shallow trays saturate faster and provide inconsistent performance

Air distribution: Uneven airflow causes localised breakthrough

Simply adding “more carbon” without addressing these points rarely solves odour problems.

Types of Carbon Used in Kitchen Odour Control

Different cooking processes generate different odour profiles. As a result, carbon selection matters.

Common options include:

Standard activated carbon: Effective for general cooking odours

Impregnated carbon: Enhanced performance for specific compounds (e.g. sulphur-based odours)

Pelletised vs granular formats: Chosen based on pressure drop and airflow stability

Correct carbon selection should be based on the menu, cooking methods, and proximity to receptors.

Signs of Carbon Filter Breakthrough

In commercial kitchens, carbon does not fail suddenly - it degrades.

Typical warning signs include:

Odours noticeable only at certain times of day

Complaints increasing during peak cooking periods

No visible smoke, but persistent smell at discharge

By the time odours are constant, the carbon is usually fully saturated and overdue replacement.

Maintenance and Replacement Expectations

Carbon filters are consumables, not fit-and-forget components.

In restaurant kitchens, realistic replacement intervals depend on:

Cooking load and hours of operation

Effectiveness of upstream filtration

Airflow rate through the carbon bed

Without proper upstream grease and smoke removal, carbon life can reduce from years to a matter of weeks.

Routine monitoring - including pressure drop and odour checks - helps avoid reactive replacements and neighbour complaints.

Carbon Filters and Environmental Health Complaints

From an Environmental Health perspective, carbon filters are often the final barrier preventing odour nuisance.

However, EHOs will typically look beyond the carbon itself and assess:

Overall system design

Maintenance records

Evidence of filtration breakdown

Poorly performing carbon filters are rarely treated as an isolated issue - they are usually seen as a symptom of wider system failure.

Getting Carbon Filtration Right in Restaurant Kitchens

Effective odour control using carbon filters relies on:

Correct placement at the end of the filtration train

Proper airflow and dwell time design

Carbon selection matched to cooking processes

Planned maintenance and timely replacement

When specified and maintained correctly, carbon filters provide reliable odour control and help restaurant kitchens operate without complaints, restrictions, or enforcement action.

We design and supply complete kitchen-extract and industrial air-filtration systems that quietly solve grease, smoke and odour, and keep you compliant. Since 2004, our team has supported restaurants and operators across the UK and Europe with specification, install support and ongoing maintenance.

We design and supply complete kitchen-extract and industrial air-filtration systems that quietly solve grease, smoke and odour, and keep you compliant. Since 2004, our team has supported restaurants and operators across the UK and Europe with specification, install support and ongoing maintenance.

We design and supply complete kitchen-extract and industrial air-filtration systems that quietly solve grease, smoke and odour, and keep you compliant. Since 2004, our team has supported restaurants and operators across the UK and Europe with specification, install support and ongoing maintenance.

Hook, Camden Town

Extechnology delivered an odour control solution to support planning and neighbour acceptance while keeping pressure drops predictable.

Hoxton Hotel, Holborn

High‑efficiency ESP stages with low static and washable cells, supporting reliable operation and simplified servicing for a busy hospitality environment.

Fuller’s — The Blue Boat

Combination of UV‑C/ozone and carbon stages to reduce cooking odours, integrated with upstream grease control for a compact plant room footprint.

Discover More Insights

Discover More Insights

Commercial Kitchen Filtration

Dec 23, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Commercial Kitchen Filtration

Dec 23, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Commercial Kitchen Filtration

Dec 23, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Commercial Kitchen Filtration

Dec 19, 2025

Air Filtration Systems for Restaurants

In a commercial restaurant kitchen, air filtration isn’t a “nice to have” - it’s fundamental to safety, compliance, and day-to-day performance. Cooking processes generate grease, smoke, heat, and odours that must be properly captured and treated before air is discharged.

Commercial Kitchen Filtration

Dec 19, 2025

Air Filtration Systems for Restaurants

In a commercial restaurant kitchen, air filtration isn’t a “nice to have” - it’s fundamental to safety, compliance, and day-to-day performance. Cooking processes generate grease, smoke, heat, and odours that must be properly captured and treated before air is discharged.

Commercial Kitchen Filtration

Dec 19, 2025

Air Filtration Systems for Restaurants

In a commercial restaurant kitchen, air filtration isn’t a “nice to have” - it’s fundamental to safety, compliance, and day-to-day performance. Cooking processes generate grease, smoke, heat, and odours that must be properly captured and treated before air is discharged.

Commercial Kitchen Filtration

Dec 11, 2025

Fire Safety and ESP Units: Reducing Risk in Grease-Heavy Commercial Kitchens

Grease accumulation within ductwork is one of the primary fire risks in commercial kitchens. ESP units play an important role in reducing this risk by...

Commercial Kitchen Filtration

Dec 11, 2025

Fire Safety and ESP Units: Reducing Risk in Grease-Heavy Commercial Kitchens

Grease accumulation within ductwork is one of the primary fire risks in commercial kitchens. ESP units play an important role in reducing this risk by...

Commercial Kitchen Filtration

Dec 11, 2025

Fire Safety and ESP Units: Reducing Risk in Grease-Heavy Commercial Kitchens

Grease accumulation within ductwork is one of the primary fire risks in commercial kitchens. ESP units play an important role in reducing this risk by...

Call Us Now

London Office Address:

London Phone Number:

Email Address:

Call Us Now

London Phone Number:

Email Address:

Call Us Now

London Office Address:

London Phone Number:

Email Address: