Categories

Commercial Kitchen Filtration

Our commercial kitchen filtration support commercial kitchen extraction systems, delivering safe, efficient, and compliant air handling for foodservice operations.

Categories

Commercial Kitchen Filtration

Our commercial kitchen filtration support commercial kitchen extraction systems, delivering safe, efficient, and compliant air handling for foodservice operations.

Categories

Commercial Kitchen Filtration

Our commercial kitchen filtration support commercial kitchen extraction systems, delivering safe, efficient, and compliant air handling for foodservice operations.

Commercial Kitchen Air Filtration

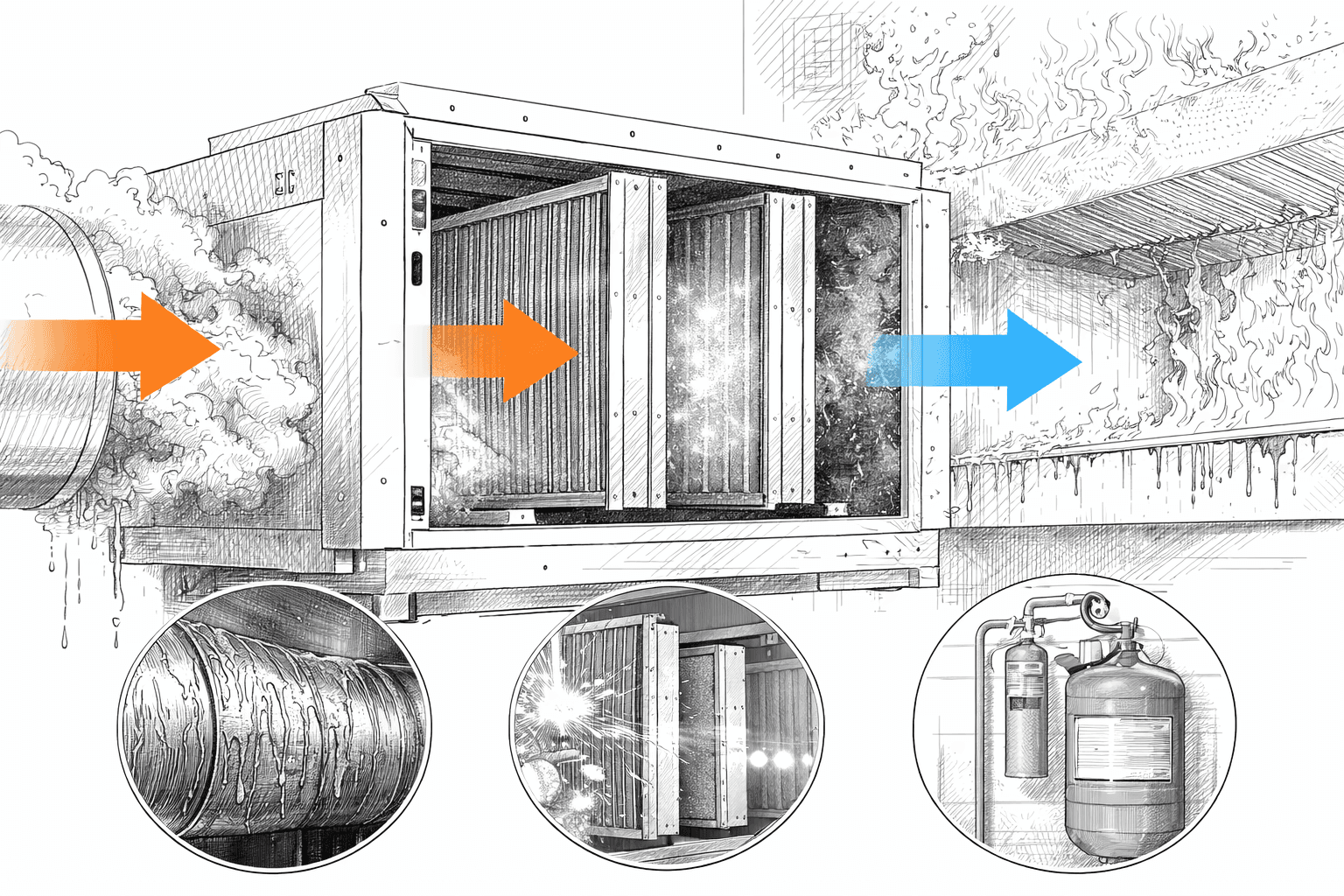

Commercial Kitchen Air Filtration removes grease, smoke and airborne pollutants generated during cooking, ensuring stable extract performance and compliance with ventilation standards. For high-duty particulate reduction, see ourelectrostatic precipitator(ESPs). These systems form the backbone of effective commercial kitchen ventilation, helping operators maintain hygiene, safety and environmental performance.

Why Kitchen Filtration?

Safer, cleaner extraction:Effective filtration removes grease aerosols and smoke close to the source, reducing fire risk and maintaining stable airflow throughout the extraction system. This supports DW/172 design principles and prevents duct contamination.Protects downstream odour stages:Removing grease and particulate before it reaches carbon stages significantly improves odour-control performance and extends carbon bed life — essential for planning compliance and EMAQ+ high-risk sites.

How It Works

Primary grease and smoke capture:Commercial Kitchen Filtration uses mechanical filters, ESPs or multi-stage configurations to reduce particulate loading and stabilise extraction rates during peak cooking hours.Designed for cooking duty:Filtration stages are matched to cooking style, airflow volume and site constraints, delivering reliable, compliant performance in restaurants, takeaways, pubs and commercial catering environments.

For more information on EMAQ+,DW172, commercial filtration and industrial air filtration, view ourblog.

Commercial Kitchen Air Filtration

Commercial Kitchen Air Filtration removes grease, smoke and airborne pollutants generated during cooking, ensuring stable extract performance and compliance with ventilation standards. For high-duty particulate reduction, see ourelectrostatic precipitator(ESPs). These systems form the backbone of effective commercial kitchen ventilation, helping operators maintain hygiene, safety and environmental performance.

Why Kitchen Filtration?

Safer, cleaner extraction:Effective filtration removes grease aerosols and smoke close to the source, reducing fire risk and maintaining stable airflow throughout the extraction system. This supports DW/172 design principles and prevents duct contamination.Protects downstream odour stages:Removing grease and particulate before it reaches carbon stages significantly improves odour-control performance and extends carbon bed life — essential for planning compliance and EMAQ+ high-risk sites.

How It Works

Primary grease and smoke capture:Commercial Kitchen Filtration uses mechanical filters, ESPs or multi-stage configurations to reduce particulate loading and stabilise extraction rates during peak cooking hours.Designed for cooking duty:Filtration stages are matched to cooking style, airflow volume and site constraints, delivering reliable, compliant performance in restaurants, takeaways, pubs and commercial catering environments.

For more information on EMAQ+,DW172, commercial filtration and industrial air filtration, view ourblog.

Commercial Kitchen Air Filtration

Commercial Kitchen Air Filtration removes grease, smoke and airborne pollutants generated during cooking, ensuring stable extract performance and compliance with ventilation standards. For high-duty particulate reduction, see ourelectrostatic precipitator(ESPs). These systems form the backbone of effective commercial kitchen ventilation, helping operators maintain hygiene, safety and environmental performance.

Why Kitchen Filtration?

Safer, cleaner extraction:Effective filtration removes grease aerosols and smoke close to the source, reducing fire risk and maintaining stable airflow throughout the extraction system. This supports DW/172 design principles and prevents duct contamination.Protects downstream odour stages:Removing grease and particulate before it reaches carbon stages significantly improves odour-control performance and extends carbon bed life — essential for planning compliance and EMAQ+ high-risk sites.

How It Works

Primary grease and smoke capture:Commercial Kitchen Filtration uses mechanical filters, ESPs or multi-stage configurations to reduce particulate loading and stabilise extraction rates during peak cooking hours.Designed for cooking duty:Filtration stages are matched to cooking style, airflow volume and site constraints, delivering reliable, compliant performance in restaurants, takeaways, pubs and commercial catering environments.

For more information on EMAQ+,DW172, commercial filtration and industrial air filtration, view ourblog.

Call Us Now

London Office Address:

London Phone Number:

Email Address:

Call Us Now

London Phone Number:

Email Address:

Call Us Now

London Office Address:

London Phone Number:

Email Address: