Electrostatic Precipitator

15 Feb 2026

Duct Design and ESP Performance in Commercial Kitchens

Electrostatic precipitator (ESP) units are widely used in commercial kitchen extraction systems to remove grease, smoke and airborne particulates. However,...

Why Correct Duct Design Is Critical to ESP Performance in Commercial Kitchens

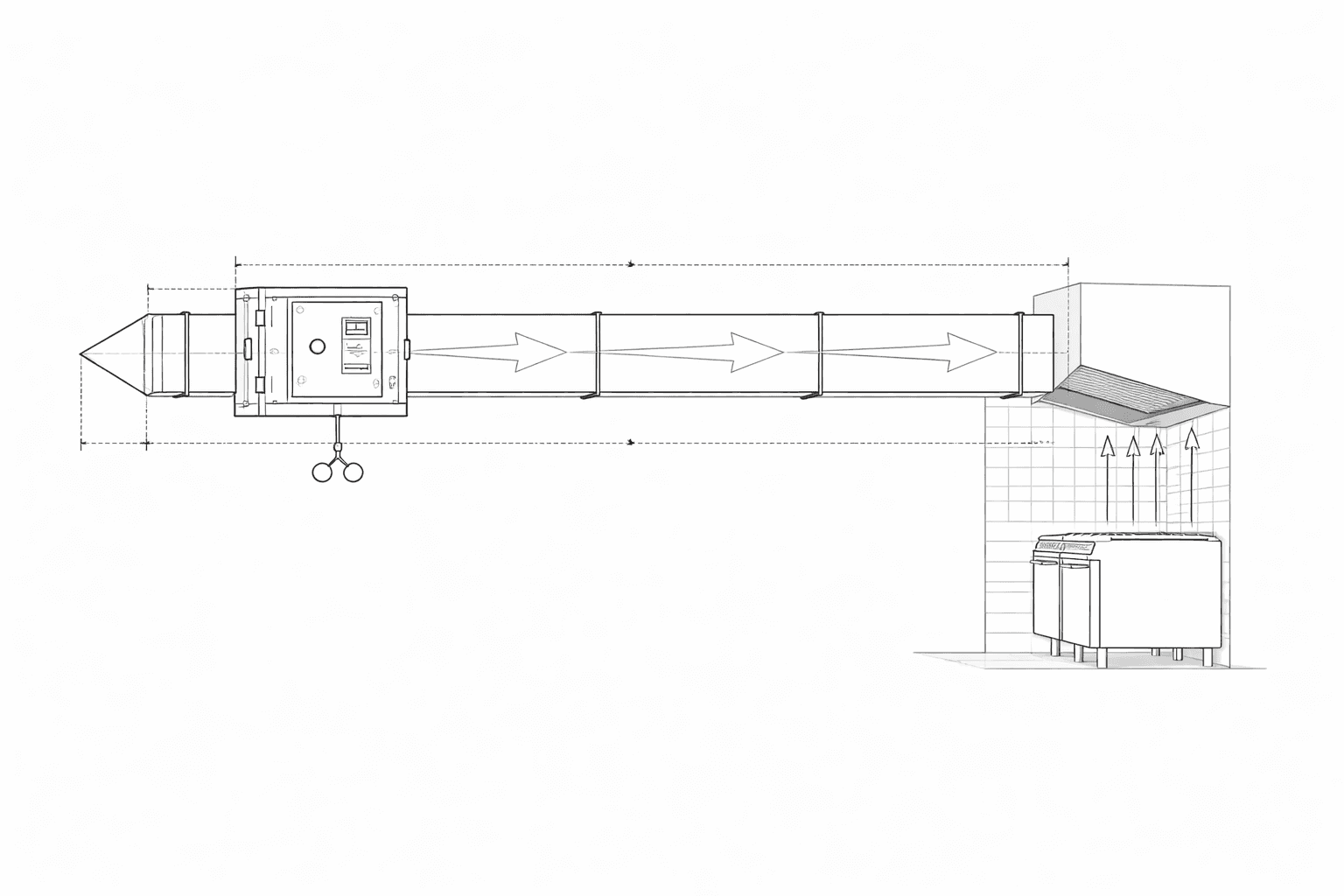

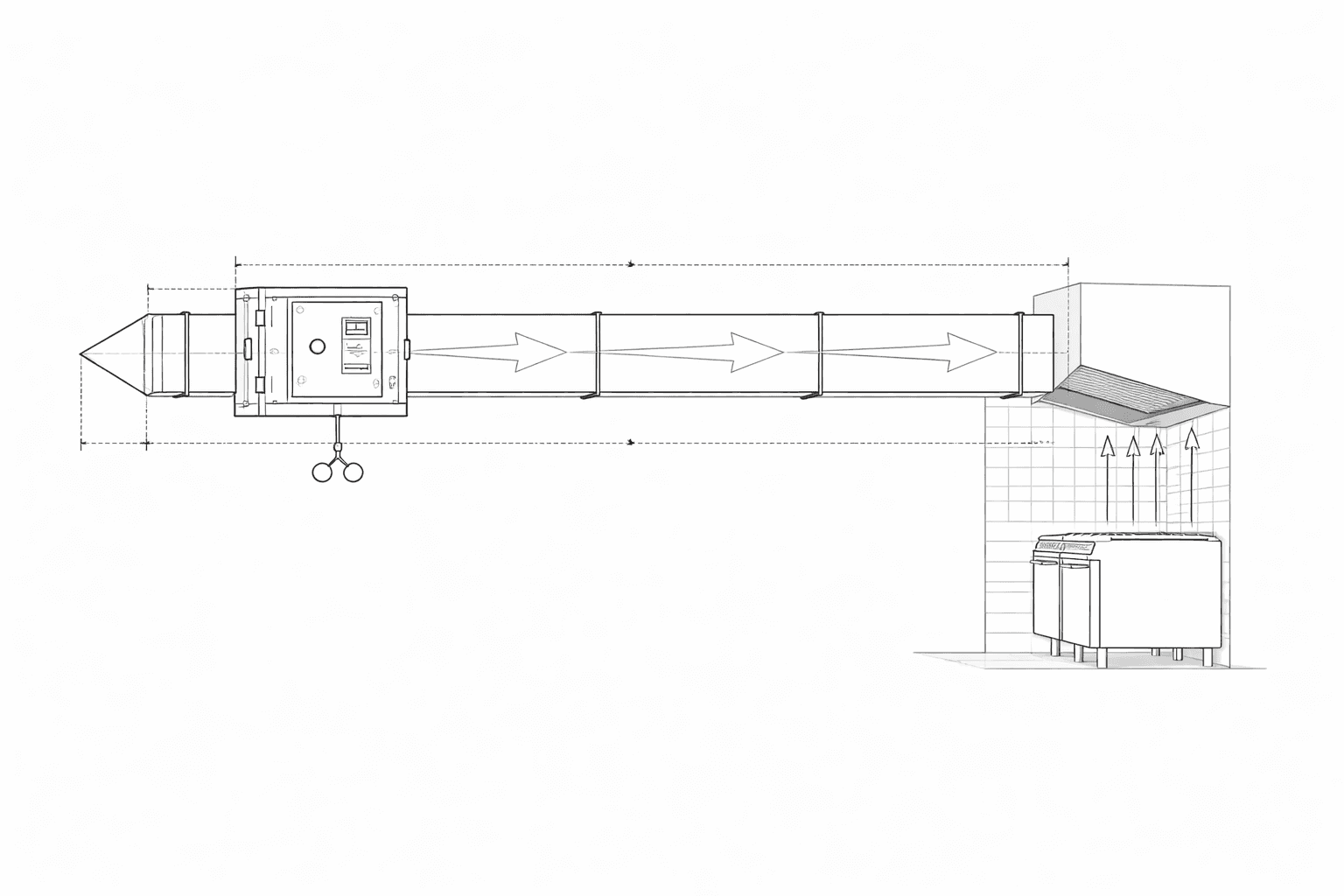

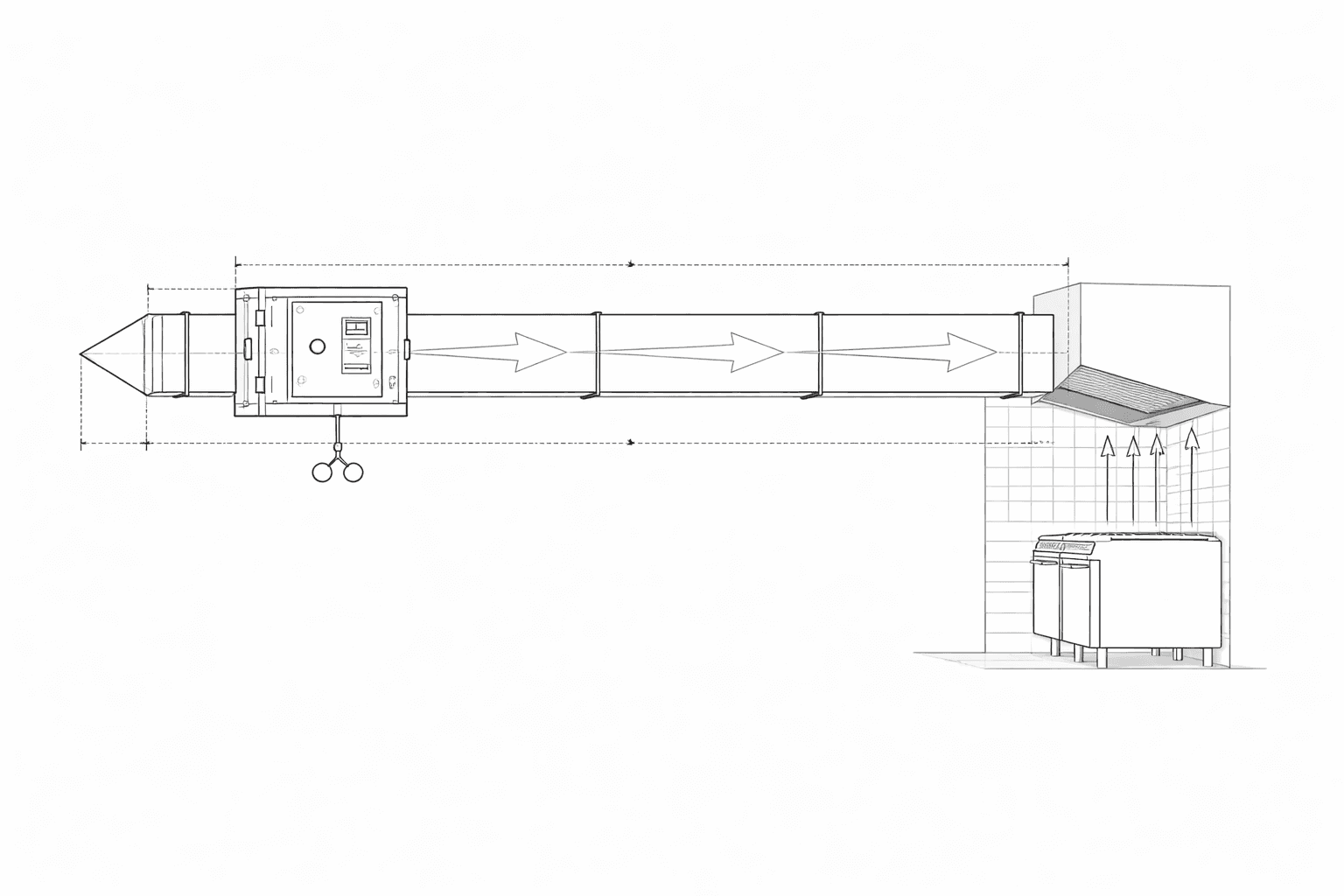

Electrostatic precipitator (ESP) units are widely used in commercial kitchen extraction systems to remove grease, smoke and airborne particulates. However, even the most advanced ESP unit will underperform if the ductwork feeding it is incorrectly designed.

In commercial kitchens, ESP performance is not just about the unit itself — it is fundamentally linked to duct velocities, airflow stability, and compliant duct transitions. Poor duct design can “suffocate” airflow, increase pressure losses, and significantly reduce filtration efficiency.

Duct Velocity: Getting the Balance Right

Ductwork must be designed to handle the required airflow while maintaining appropriate air velocities. If velocities are too high, air passes through the system too quickly, reducing the effectiveness of the ESP. If velocities are too low, grease and particulates can settle within the ductwork, increasing fire risk and maintenance requirements.

Correct duct sizing ensures stable airflow through the ESP unit, consistent face velocity across the electrostatic cells, and effective particulate charging and collection. Duct velocities should always be calculated based on the required kitchen extract volume, rather than forcing airflow through undersized ductwork.

The Impact of Poor Transitions and Reducers

One of the most common issues seen on site is poorly designed duct connections to ESP units. Sharp reducers, abrupt transitions, or non-compliant duct fittings can severely restrict airflow and create turbulence upstream of the ESP.

All ductwork connections, transitions and reducers should be designed and manufactured in accordance with DW144 standards. Properly formed reducers allow airflow to transition smoothly, preventing pressure drops and uneven air distribution across the ESP cells.

Avoiding Airflow Restriction (“Suffocation”)

When ductwork is undersized or poorly adapted, the system effectively becomes choked. This restriction reduces airflow through the entire extraction system, impacting capture efficiency at the canopy, ESP filtration performance, and fan duty and lifespan.

Straight Duct Requirements Around ESP Units

ESP units perform best when airflow entering the unit is stable and evenly distributed. Excessive bends, offsets, or dampers immediately upstream or downstream of the ESP can introduce turbulence and uneven velocities.

Where possible, straight duct runs should be provided before and after the ESP unit to allow airflow to stabilise. This helps maximise dwell time within the ESP cells and ensures consistent grease and particulate removal.

Designing for Performance from Canopy to Discharge

A successful commercial kitchen filtration system must be considered as a whole. From canopy capture through to final discharge, ductwork design plays a critical role in system efficiency, safety, and long-term reliability.

By ensuring correct duct velocities, DW144-compliant transitions, and adequate straight duct runs, ESP units can perform as intended — delivering effective filtration and supporting a cleaner, safer kitchen environment.

We design and supply complete kitchen-extract and industrial air-filtration systems that quietly solve grease, smoke and odour, and keep you compliant. Since 2004, our team has supported restaurants and operators across the UK and Europe with specification, install support and ongoing maintenance.

We design and supply complete kitchen-extract and industrial air-filtration systems that quietly solve grease, smoke and odour, and keep you compliant. Since 2004, our team has supported restaurants and operators across the UK and Europe with specification, install support and ongoing maintenance.

We design and supply complete kitchen-extract and industrial air-filtration systems that quietly solve grease, smoke and odour, and keep you compliant. Since 2004, our team has supported restaurants and operators across the UK and Europe with specification, install support and ongoing maintenance.

Hook, Camden Town

Extechnology delivered an odour control solution to support planning and neighbour acceptance while keeping pressure drops predictable.

Hoxton Hotel, Holborn

High‑efficiency ESP stages with low static and washable cells, supporting reliable operation and simplified servicing for a busy hospitality environment.

Fuller’s — The Blue Boat

Combination of UV‑C/ozone and carbon stages to reduce cooking odours, integrated with upstream grease control for a compact plant room footprint.

Discover More Insights

Discover More Insights

Commercial Kitchen Filtration

Dec 23, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Commercial Kitchen Filtration

Dec 23, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Commercial Kitchen Filtration

Dec 23, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Odour Control

Dec 15, 2025

Odour Control Carbon Filters in Commercial Kitchens

Carbon filters are one of the most widely specified odour control solutions in restaurant kitchens — and also one of the most misunderstood.

Odour Control

Dec 15, 2025

Odour Control Carbon Filters in Commercial Kitchens

Carbon filters are one of the most widely specified odour control solutions in restaurant kitchens — and also one of the most misunderstood.

Odour Control

Dec 15, 2025

Odour Control Carbon Filters in Commercial Kitchens

Carbon filters are one of the most widely specified odour control solutions in restaurant kitchens — and also one of the most misunderstood.

Commercial Kitchen Filtration

Dec 19, 2025

Air Filtration Systems for Restaurants

In a commercial restaurant kitchen, air filtration isn’t a “nice to have” - it’s fundamental to safety, compliance, and day-to-day performance. Cooking processes generate grease, smoke, heat, and odours that must be properly captured and treated before air is discharged.

Commercial Kitchen Filtration

Dec 19, 2025

Air Filtration Systems for Restaurants

In a commercial restaurant kitchen, air filtration isn’t a “nice to have” - it’s fundamental to safety, compliance, and day-to-day performance. Cooking processes generate grease, smoke, heat, and odours that must be properly captured and treated before air is discharged.

Commercial Kitchen Filtration

Dec 19, 2025

Air Filtration Systems for Restaurants

In a commercial restaurant kitchen, air filtration isn’t a “nice to have” - it’s fundamental to safety, compliance, and day-to-day performance. Cooking processes generate grease, smoke, heat, and odours that must be properly captured and treated before air is discharged.

Call Us Now

London Office Address:

London Phone Number:

Email Address:

Call Us Now

London Phone Number:

Email Address:

Call Us Now

London Office Address:

London Phone Number:

Email Address: