Sep 2, 2025

Maintenance That Saves Money: ESP Cells, Carbon & UV‑C Schedules

Dan Clark

Technical Director, X Technology

Set realistic service intervals for pre‑filters, ESP cells, carbon and UV‑C. Lower call‑outs, stable pressure drop and better odour control — without over‑servicing.

Sep 2, 2025

Maintenance That Saves Money: ESP Cells, Carbon & UV‑C Schedules

Dan Clark

Technical Director, X Technology

Set realistic service intervals for pre‑filters, ESP cells, carbon and UV‑C. Lower call‑outs, stable pressure drop and better odour control — without over‑servicing.

Sep 2, 2025

Maintenance That Saves Money: ESP Cells, Carbon & UV‑C Schedules

Dan Clark

Technical Director, X Technology

Set realistic service intervals for pre‑filters, ESP cells, carbon and UV‑C. Lower call‑outs, stable pressure drop and better odour control — without over‑servicing.

Maintenance That Saves Money: ESP Cells, Carbon & UV‑C Schedules

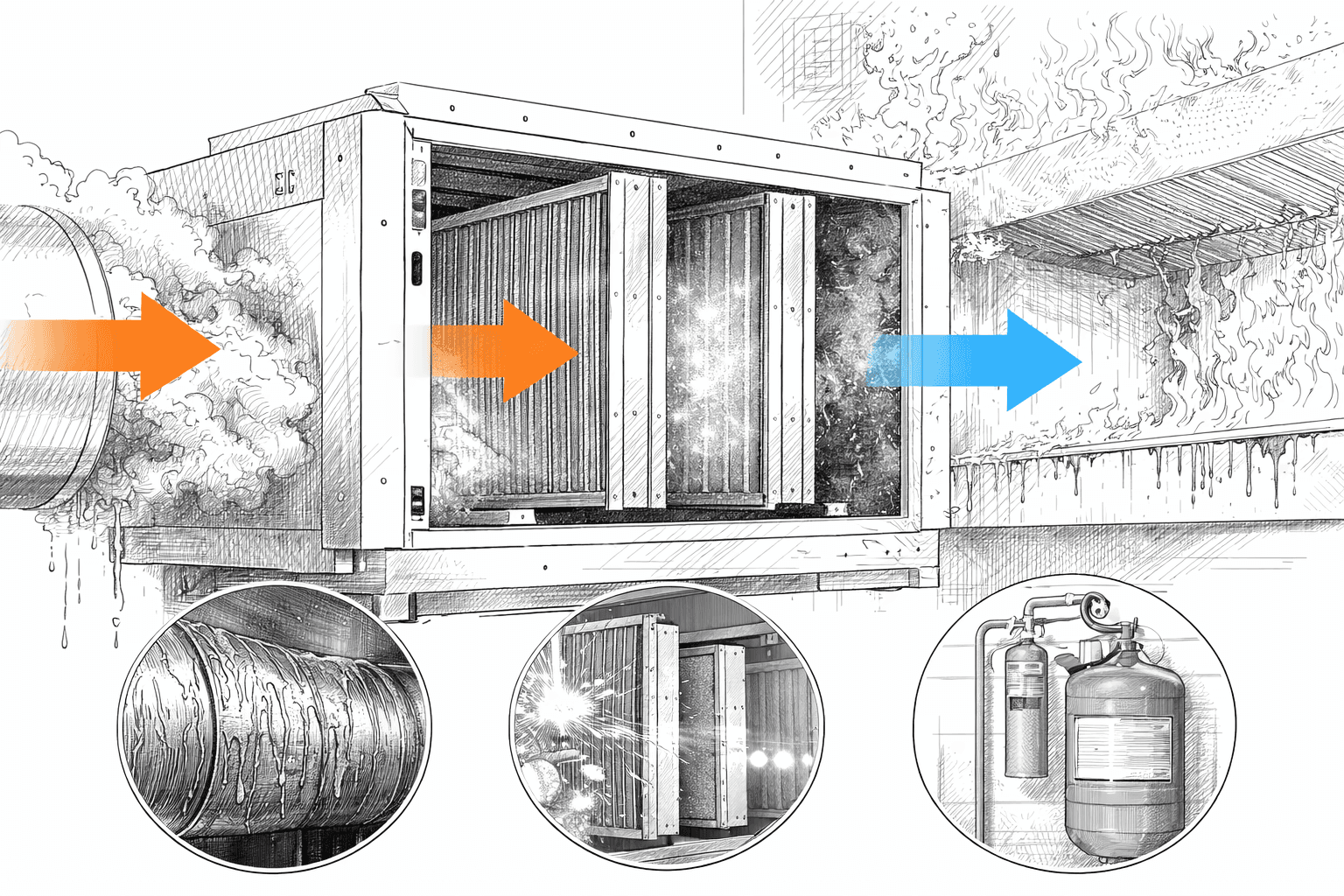

Maintenance in the commercial kitchen filtration world is often seen as a necessary cost, but in commercial kitchens it’s actually one of the strongest levers you have for reducing downtime, stabilising airflow and preventing expensive odour or smoke incidents. When your filtration stages are clean and your airflow is predictable, fans work less, ducts stay safer, and call-outs drop sharply. Below is a practical, real-world schedule that operators, FM teams and consultants can adapt to any site.

Commercial Kitchen Pre-Filters

Pre-filters protect everything downstream, so they need regular attention.Check them weekly and wash them in warm water with a suitable degreaser. Make sure they are fully dry before refitting, otherwise moisture can cause corrosion in ESP cells and disrupt the ionisation process.Typical interval for washing or replacement is 1–4 weeks depending on the site’s cooking load, hours, and canopy performance. High-grease sites will need more frequent checks.

Commercial Kitchen ESP Collector Cells

ESP cells do the hard work of capturing grease and smoke particulates. When they load up, efficiency drops and pressure increases. A cleaning interval of every 4–8 weeks suits most commercial kitchens, but heavy-duty restaurants or high-temperature cooking may need shorter cycles. Clean with approved alkaline cleaners, rinse thoroughly, and allow complete drying before reinstating. Always document each service in a logbook - it’s valuable for TR19, EHOs, insurers and landlords.

Activated Carbon

Carbon filters are your main odour stage, but they only work effectively when upstream filtration is performing.Plan change-outs before breakthrough rather than waiting until complaints arise. If odour increases between scheduled visits, it’s almost always due to an upstream issue: dirty pre-filters, overloaded ESP cells, airflow reduction, or bypass.A quick airflow verification and ESP check should be your first response before replacing carbon unnecessarily.

UV-C / Ozone Stages

UV-C and ozone systems have very specific maintenance needs.Lamps typically need replacement around 12,000–13,000 operating hours to maintain correct output. After works, verify door interlocks, airflow proving switches and safety interlocks — these ensure ozone is never generated without adequate airflow.Never operate ozone systems during cleaning or when the fan is off. Proper safety checks protect staff and ensure compliance.

Why Schedules Pay Back

A structured maintenance plan isn’t just compliance - it’s a financial strategy. Lower pressure drop means reduced fan energy, quieter operation, and fewer overheating faults. Cleaner ducts help maintain TR19 hygiene intervals, reduce fire load and extend the lifespan of the extract system. Predictable planned visits prevent emergency call-outs during peak trading hours and keep the kitchen stable when it matters most.

Prefer to Outsource Maintenance?

Our sister company, Arden Environmental, delivers planned maintenance for ESP, carbon, UV-C, ozone and complete extract systems. If you’d rather focus on running your kitchen, we’ll keep your airflow, odour and compliance fully under control.

Maintenance That Saves Money: ESP Cells, Carbon & UV‑C Schedules

Maintenance in the commercial kitchen filtration world is often seen as a necessary cost, but in commercial kitchens it’s actually one of the strongest levers you have for reducing downtime, stabilising airflow and preventing expensive odour or smoke incidents. When your filtration stages are clean and your airflow is predictable, fans work less, ducts stay safer, and call-outs drop sharply. Below is a practical, real-world schedule that operators, FM teams and consultants can adapt to any site.

Commercial Kitchen Pre-Filters

Pre-filters protect everything downstream, so they need regular attention.Check them weekly and wash them in warm water with a suitable degreaser. Make sure they are fully dry before refitting, otherwise moisture can cause corrosion in ESP cells and disrupt the ionisation process.Typical interval for washing or replacement is 1–4 weeks depending on the site’s cooking load, hours, and canopy performance. High-grease sites will need more frequent checks.

Commercial Kitchen ESP Collector Cells

ESP cells do the hard work of capturing grease and smoke particulates. When they load up, efficiency drops and pressure increases. A cleaning interval of every 4–8 weeks suits most commercial kitchens, but heavy-duty restaurants or high-temperature cooking may need shorter cycles. Clean with approved alkaline cleaners, rinse thoroughly, and allow complete drying before reinstating. Always document each service in a logbook - it’s valuable for TR19, EHOs, insurers and landlords.

Activated Carbon

Carbon filters are your main odour stage, but they only work effectively when upstream filtration is performing.Plan change-outs before breakthrough rather than waiting until complaints arise. If odour increases between scheduled visits, it’s almost always due to an upstream issue: dirty pre-filters, overloaded ESP cells, airflow reduction, or bypass.A quick airflow verification and ESP check should be your first response before replacing carbon unnecessarily.

UV-C / Ozone Stages

UV-C and ozone systems have very specific maintenance needs.Lamps typically need replacement around 12,000–13,000 operating hours to maintain correct output. After works, verify door interlocks, airflow proving switches and safety interlocks — these ensure ozone is never generated without adequate airflow.Never operate ozone systems during cleaning or when the fan is off. Proper safety checks protect staff and ensure compliance.

Why Schedules Pay Back

A structured maintenance plan isn’t just compliance - it’s a financial strategy. Lower pressure drop means reduced fan energy, quieter operation, and fewer overheating faults. Cleaner ducts help maintain TR19 hygiene intervals, reduce fire load and extend the lifespan of the extract system. Predictable planned visits prevent emergency call-outs during peak trading hours and keep the kitchen stable when it matters most.

Prefer to Outsource Maintenance?

Our sister company, Arden Environmental, delivers planned maintenance for ESP, carbon, UV-C, ozone and complete extract systems. If you’d rather focus on running your kitchen, we’ll keep your airflow, odour and compliance fully under control.

Maintenance That Saves Money: ESP Cells, Carbon & UV‑C Schedules

Maintenance in the commercial kitchen filtration world is often seen as a necessary cost, but in commercial kitchens it’s actually one of the strongest levers you have for reducing downtime, stabilising airflow and preventing expensive odour or smoke incidents. When your filtration stages are clean and your airflow is predictable, fans work less, ducts stay safer, and call-outs drop sharply. Below is a practical, real-world schedule that operators, FM teams and consultants can adapt to any site.

Commercial Kitchen Pre-Filters

Pre-filters protect everything downstream, so they need regular attention.Check them weekly and wash them in warm water with a suitable degreaser. Make sure they are fully dry before refitting, otherwise moisture can cause corrosion in ESP cells and disrupt the ionisation process.Typical interval for washing or replacement is 1–4 weeks depending on the site’s cooking load, hours, and canopy performance. High-grease sites will need more frequent checks.

Commercial Kitchen ESP Collector Cells

ESP cells do the hard work of capturing grease and smoke particulates. When they load up, efficiency drops and pressure increases. A cleaning interval of every 4–8 weeks suits most commercial kitchens, but heavy-duty restaurants or high-temperature cooking may need shorter cycles. Clean with approved alkaline cleaners, rinse thoroughly, and allow complete drying before reinstating. Always document each service in a logbook - it’s valuable for TR19, EHOs, insurers and landlords.

Activated Carbon

Carbon filters are your main odour stage, but they only work effectively when upstream filtration is performing.Plan change-outs before breakthrough rather than waiting until complaints arise. If odour increases between scheduled visits, it’s almost always due to an upstream issue: dirty pre-filters, overloaded ESP cells, airflow reduction, or bypass.A quick airflow verification and ESP check should be your first response before replacing carbon unnecessarily.

UV-C / Ozone Stages

UV-C and ozone systems have very specific maintenance needs.Lamps typically need replacement around 12,000–13,000 operating hours to maintain correct output. After works, verify door interlocks, airflow proving switches and safety interlocks — these ensure ozone is never generated without adequate airflow.Never operate ozone systems during cleaning or when the fan is off. Proper safety checks protect staff and ensure compliance.

Why Schedules Pay Back

A structured maintenance plan isn’t just compliance - it’s a financial strategy. Lower pressure drop means reduced fan energy, quieter operation, and fewer overheating faults. Cleaner ducts help maintain TR19 hygiene intervals, reduce fire load and extend the lifespan of the extract system. Predictable planned visits prevent emergency call-outs during peak trading hours and keep the kitchen stable when it matters most.

Prefer to Outsource Maintenance?

Our sister company, Arden Environmental, delivers planned maintenance for ESP, carbon, UV-C, ozone and complete extract systems. If you’d rather focus on running your kitchen, we’ll keep your airflow, odour and compliance fully under control.

Call Us Now

London Office Address:

London Phone Number:

Email Address:

Call Us Now

London Phone Number:

Email Address:

Call Us Now

London Office Address:

London Phone Number:

Email Address: