Electrostatic Precipitator

15 Feb 2026

How Airflow Rates Affect ESP Performance in Commercial Kitchens

Correct airflow rates are critical to the effective operation of electrostatic precipitator (ESP) units in commercial kitchen extraction systems. While ESPs...

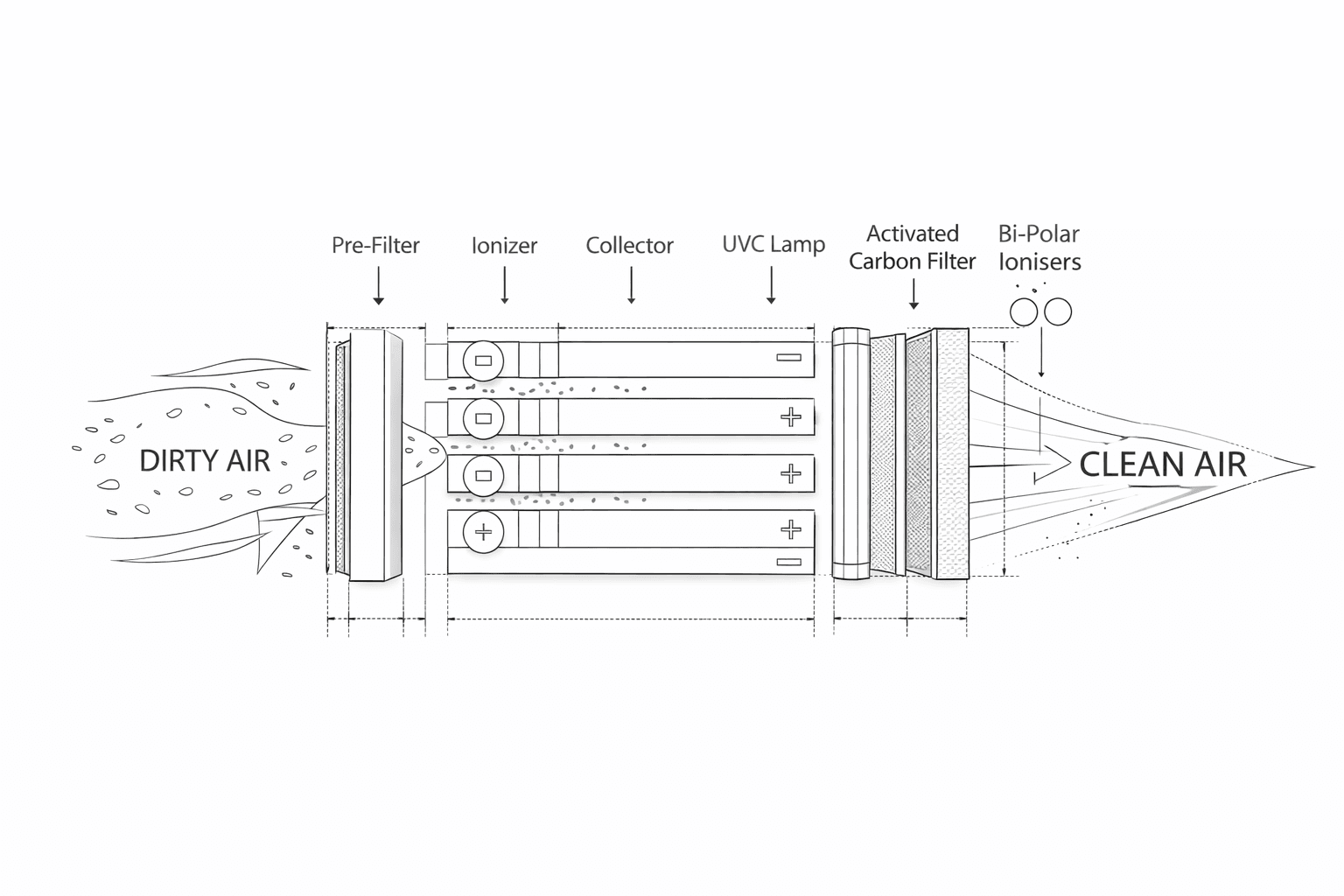

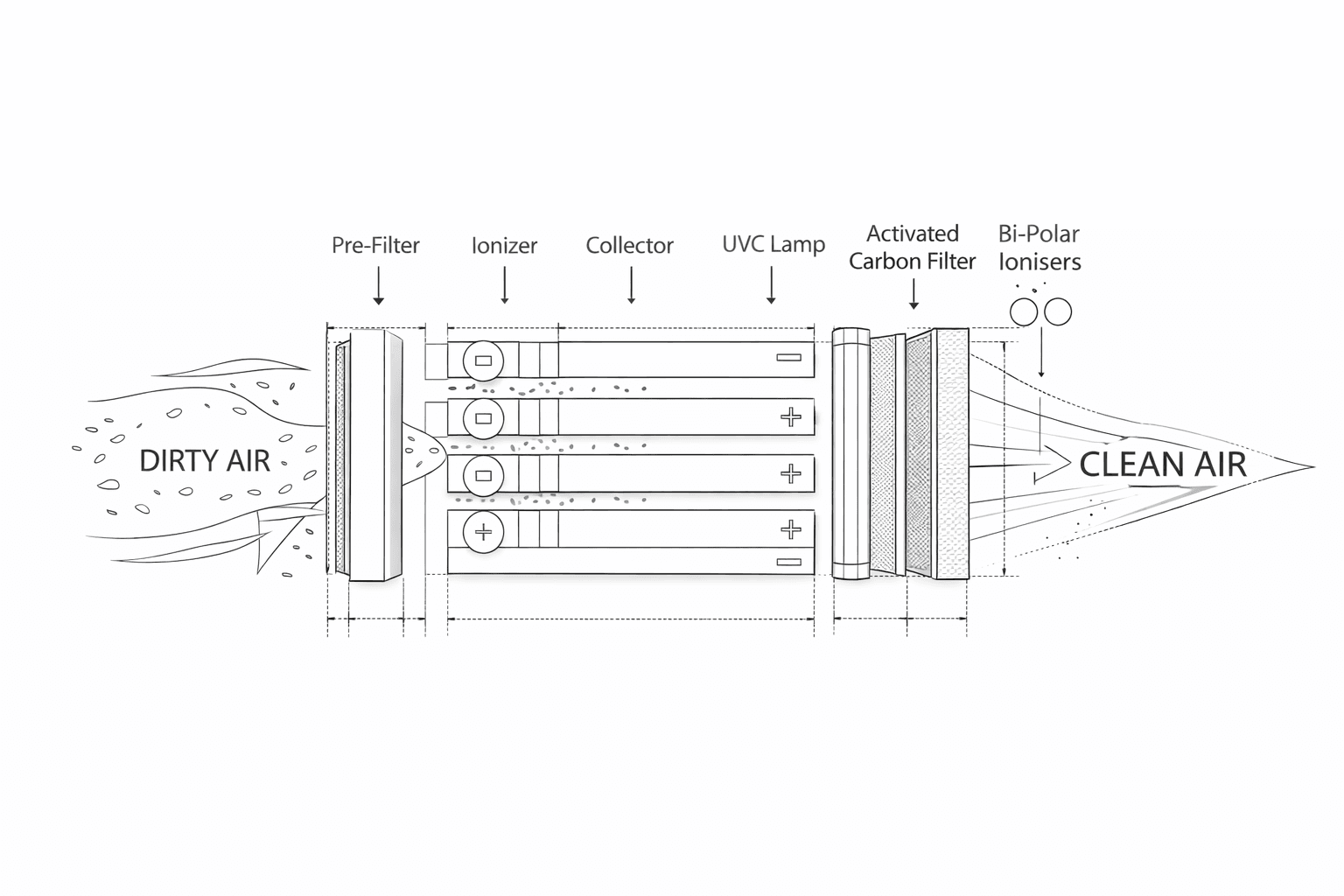

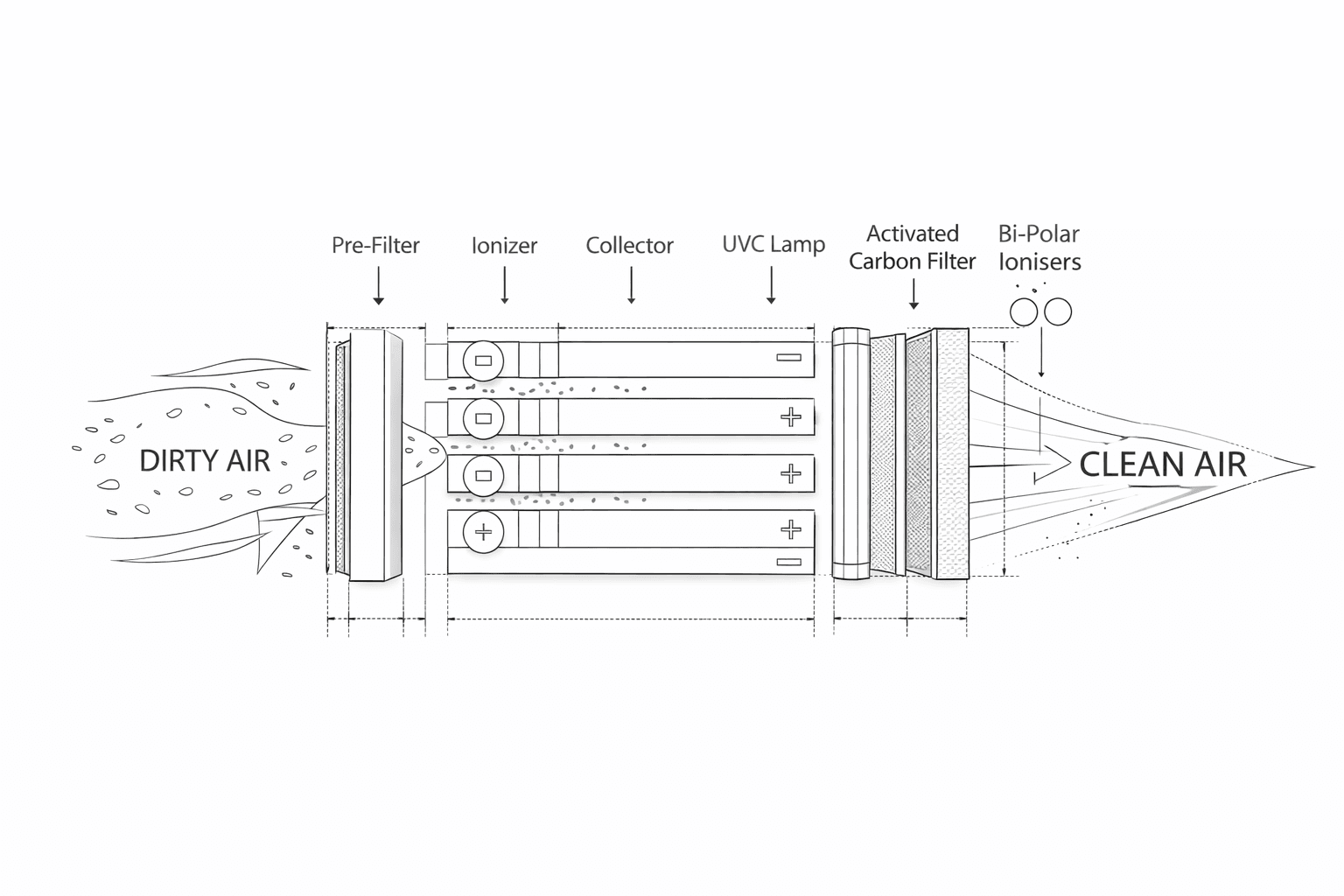

Correct airflow rates are critical to the effective operation of electrostatic precipitator (ESP) units in commercial kitchen filtration extraction systems. While ESPs are highly efficient at removing grease and smoke, their performance is directly influenced by air velocity and dwell time through the filtration cells.

If airflow is not correctly designed, particulates can pass through the ESP too quickly, reducing collection efficiency and allowing grease and smoke to remain in the airstream.

The Relationship Between Velocity and Dwell Time

ESP units rely on sufficient dwell time to electrically charge airborne particulates and collect them on the plates. When air velocity is too high, dwell time is reduced, meaning grease particles are not fully charged, smoke can bypass the collection plates, and filtration efficiency is compromised.

Conversely, airflow that is too low can lead to grease drop-out upstream and increased contamination within ductwork.

Designing Airflow to Match ESP Capability

Airflow rates must be aligned with the ESP unit’s design parameters. Oversizing fans or forcing higher airflow through an ESP than it is rated for can significantly reduce effectiveness.

Correct airflow design ensures stable face velocity across ESP cells, effective particulate charging, and consistent performance under peak cooking conditions. Airflow should always be engineered around the kitchen duty and cooking load, not assumed or increased arbitrarily.

System Performance Depends on Balance

ESP units perform best when airflow, duct size, fan selection and filtration stages are balanced as part of a complete system. Proper airflow design ensures grease and smoke are removed efficiently, protecting downstream components and maintaining compliance.

We design and supply complete kitchen-extract and industrial air-filtration systems that quietly solve grease, smoke and odour, and keep you compliant. Since 2004, our team has supported restaurants and operators across the UK and Europe with specification, install support and ongoing maintenance.

We design and supply complete kitchen-extract and industrial air-filtration systems that quietly solve grease, smoke and odour, and keep you compliant. Since 2004, our team has supported restaurants and operators across the UK and Europe with specification, install support and ongoing maintenance.

We design and supply complete kitchen-extract and industrial air-filtration systems that quietly solve grease, smoke and odour, and keep you compliant. Since 2004, our team has supported restaurants and operators across the UK and Europe with specification, install support and ongoing maintenance.

Hook, Camden Town

Extechnology delivered an odour control solution to support planning and neighbour acceptance while keeping pressure drops predictable.

Hoxton Hotel, Holborn

High‑efficiency ESP stages with low static and washable cells, supporting reliable operation and simplified servicing for a busy hospitality environment.

Fuller’s — The Blue Boat

Combination of UV‑C/ozone and carbon stages to reduce cooking odours, integrated with upstream grease control for a compact plant room footprint.

Discover More Insights

Discover More Insights

Commercial Kitchen Filtration

Dec 23, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Commercial Kitchen Filtration

Dec 23, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Commercial Kitchen Filtration

Dec 23, 2025

Hidden Costs of Poor Kitchen Ventilation in Restaurants

Behind every successful restaurant is a reliable extraction and ventilation system. Its job is to remove grease, smoke, and odour from the cooking process so that clean air is safely discharged to atmosphere.

Odour Control

Dec 15, 2025

Odour Control Carbon Filters in Commercial Kitchens

Carbon filters are one of the most widely specified odour control solutions in restaurant kitchens — and also one of the most misunderstood.

Odour Control

Dec 15, 2025

Odour Control Carbon Filters in Commercial Kitchens

Carbon filters are one of the most widely specified odour control solutions in restaurant kitchens — and also one of the most misunderstood.

Odour Control

Dec 15, 2025

Odour Control Carbon Filters in Commercial Kitchens

Carbon filters are one of the most widely specified odour control solutions in restaurant kitchens — and also one of the most misunderstood.

Commercial Kitchen Filtration

Dec 19, 2025

Air Filtration Systems for Restaurants

In a commercial restaurant kitchen, air filtration isn’t a “nice to have” - it’s fundamental to safety, compliance, and day-to-day performance. Cooking processes generate grease, smoke, heat, and odours that must be properly captured and treated before air is discharged.

Commercial Kitchen Filtration

Dec 19, 2025

Air Filtration Systems for Restaurants

In a commercial restaurant kitchen, air filtration isn’t a “nice to have” - it’s fundamental to safety, compliance, and day-to-day performance. Cooking processes generate grease, smoke, heat, and odours that must be properly captured and treated before air is discharged.

Commercial Kitchen Filtration

Dec 19, 2025

Air Filtration Systems for Restaurants

In a commercial restaurant kitchen, air filtration isn’t a “nice to have” - it’s fundamental to safety, compliance, and day-to-day performance. Cooking processes generate grease, smoke, heat, and odours that must be properly captured and treated before air is discharged.

Call Us Now

London Office Address:

London Phone Number:

Email Address:

Call Us Now

London Phone Number:

Email Address:

Call Us Now

London Office Address:

London Phone Number:

Email Address: