Sep 10, 2025

Odour Control for Restaurants: How to Stop Neighbour Complaints

Dan Clark

Technical Director, X Technology

How to design, commission and maintain odour control for restaurants so you keep neighbours on‑side and sail through planning — including ESP, ozone/UV‑C and carbon polishing.

Sep 10, 2025

Odour Control for Restaurants: How to Stop Neighbour Complaints

Dan Clark

Technical Director, X Technology

How to design, commission and maintain odour control for restaurants so you keep neighbours on‑side and sail through planning — including ESP, ozone/UV‑C and carbon polishing.

Sep 10, 2025

Odour Control for Restaurants: How to Stop Neighbour Complaints

Dan Clark

Technical Director, X Technology

How to design, commission and maintain odour control for restaurants so you keep neighbours on‑side and sail through planning — including ESP, ozone/UV‑C and carbon polishing.

Odour Control for Restaurants: How to Stop Neighbour Complaints

Odour Control for Restaurants: How to Stop Neighbour Complaints

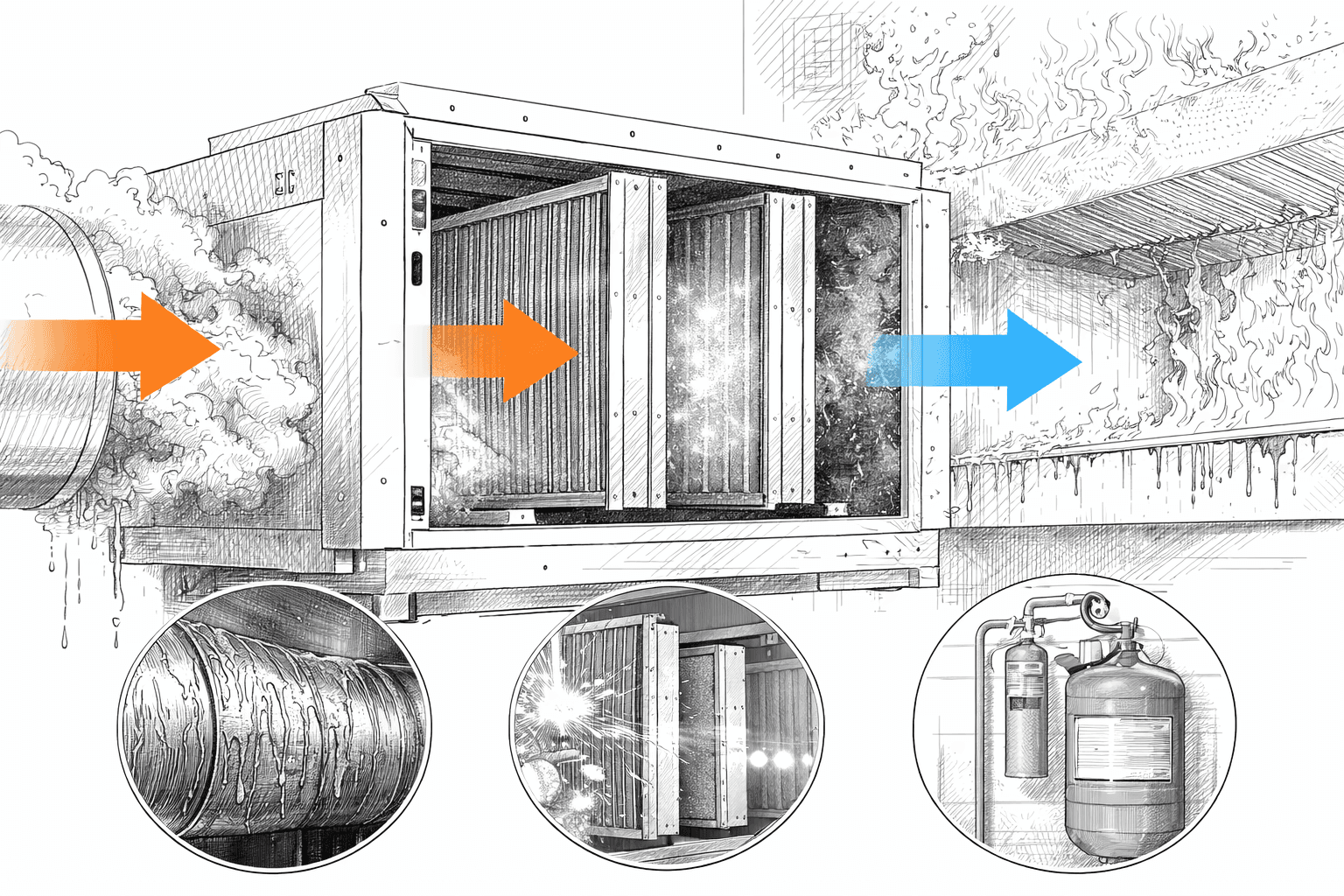

Whether you’re opening a new kitchen or firefighting complaints, the solution is the same: remove particulates, " "oxidise odours where needed, and polish with carbon. Design it right and keep it maintained — complaints fall away.

Why complaints happen

Charcoal and heavy cooking produce strong aromas and fine smoke that travel. Low discharge height or proximity to receptors amplifies impact. Poor maintenance causes breakthrough even when the design was sound.

Design the fix

ESP first : keeps grease/smoke out of the duct and off carbon media. Ozone/UV‑C : breaks down stubborn odours; interlock to airflow and access doors. Activated carbon : final polishing; set face velocity for dwell time.

Commissioning checklist

Verify airflow at the ESP and carbon modules, not just at the fan. Record ΔP across treatment stages and confirm door/airflow interlocks. Log discharge location/height and any sensitive receptors.

Maintenance that keeps you complaint‑free

Pre‑filters: weekly check; wash 1–4 weeks. ESP cells: clean 4–8 weeks depending on load. Carbon: change before breakthrough; maintain a logbook.

Troubleshooting quick wins

Restore design airflow; starved systems under‑perform on odour. Eliminate bypasses; reseat doors and replace worn gaskets. Add or expand carbon stage where dwell time is inadequate.

Need a plan? Book a free odour assessment and we’ll provide a written treatment proposal.

Odour Control for Restaurants: How to Stop Neighbour Complaints

Odour Control for Restaurants: How to Stop Neighbour Complaints

Whether you’re opening a new kitchen or firefighting complaints, the solution is the same: remove particulates, " "oxidise odours where needed, and polish with carbon. Design it right and keep it maintained — complaints fall away.

Why complaints happen

Charcoal and heavy cooking produce strong aromas and fine smoke that travel. Low discharge height or proximity to receptors amplifies impact. Poor maintenance causes breakthrough even when the design was sound.

Design the fix

ESP first : keeps grease/smoke out of the duct and off carbon media. Ozone/UV‑C : breaks down stubborn odours; interlock to airflow and access doors. Activated carbon : final polishing; set face velocity for dwell time.

Commissioning checklist

Verify airflow at the ESP and carbon modules, not just at the fan. Record ΔP across treatment stages and confirm door/airflow interlocks. Log discharge location/height and any sensitive receptors.

Maintenance that keeps you complaint‑free

Pre‑filters: weekly check; wash 1–4 weeks. ESP cells: clean 4–8 weeks depending on load. Carbon: change before breakthrough; maintain a logbook.

Troubleshooting quick wins

Restore design airflow; starved systems under‑perform on odour. Eliminate bypasses; reseat doors and replace worn gaskets. Add or expand carbon stage where dwell time is inadequate.

Need a plan? Book a free odour assessment and we’ll provide a written treatment proposal.

Odour Control for Restaurants: How to Stop Neighbour Complaints

Odour Control for Restaurants: How to Stop Neighbour Complaints

Whether you’re opening a new kitchen or firefighting complaints, the solution is the same: remove particulates, " "oxidise odours where needed, and polish with carbon. Design it right and keep it maintained — complaints fall away.

Why complaints happen

Charcoal and heavy cooking produce strong aromas and fine smoke that travel. Low discharge height or proximity to receptors amplifies impact. Poor maintenance causes breakthrough even when the design was sound.

Design the fix

ESP first : keeps grease/smoke out of the duct and off carbon media. Ozone/UV‑C : breaks down stubborn odours; interlock to airflow and access doors. Activated carbon : final polishing; set face velocity for dwell time.

Commissioning checklist

Verify airflow at the ESP and carbon modules, not just at the fan. Record ΔP across treatment stages and confirm door/airflow interlocks. Log discharge location/height and any sensitive receptors.

Maintenance that keeps you complaint‑free

Pre‑filters: weekly check; wash 1–4 weeks. ESP cells: clean 4–8 weeks depending on load. Carbon: change before breakthrough; maintain a logbook.

Troubleshooting quick wins

Restore design airflow; starved systems under‑perform on odour. Eliminate bypasses; reseat doors and replace worn gaskets. Add or expand carbon stage where dwell time is inadequate.

Need a plan? Book a free odour assessment and we’ll provide a written treatment proposal.

Call Us Now

London Office Address:

London Phone Number:

Email Address:

Call Us Now

London Phone Number:

Email Address:

Call Us Now

London Office Address:

London Phone Number:

Email Address: