Sep 6, 2025

Industrial Oil Mist Filtration: Reduce Downtime & Improve IAQ

Dan Clark

Technical Director, X Technology

A practical introduction to industrial oil mist filtration for manufacturers — how ESP and mechanical stages reduce downtime, protect machines and improve indoor air quality (IAQ).

Sep 6, 2025

Industrial Oil Mist Filtration: Reduce Downtime & Improve IAQ

Dan Clark

Technical Director, X Technology

A practical introduction to industrial oil mist filtration for manufacturers — how ESP and mechanical stages reduce downtime, protect machines and improve indoor air quality (IAQ).

Sep 6, 2025

Industrial Oil Mist Filtration: Reduce Downtime & Improve IAQ

Dan Clark

Technical Director, X Technology

A practical introduction to industrial oil mist filtration for manufacturers — how ESP and mechanical stages reduce downtime, protect machines and improve indoor air quality (IAQ).

Industrial Oil Mist Filtration: Reduce Downtime & Improve IAQ

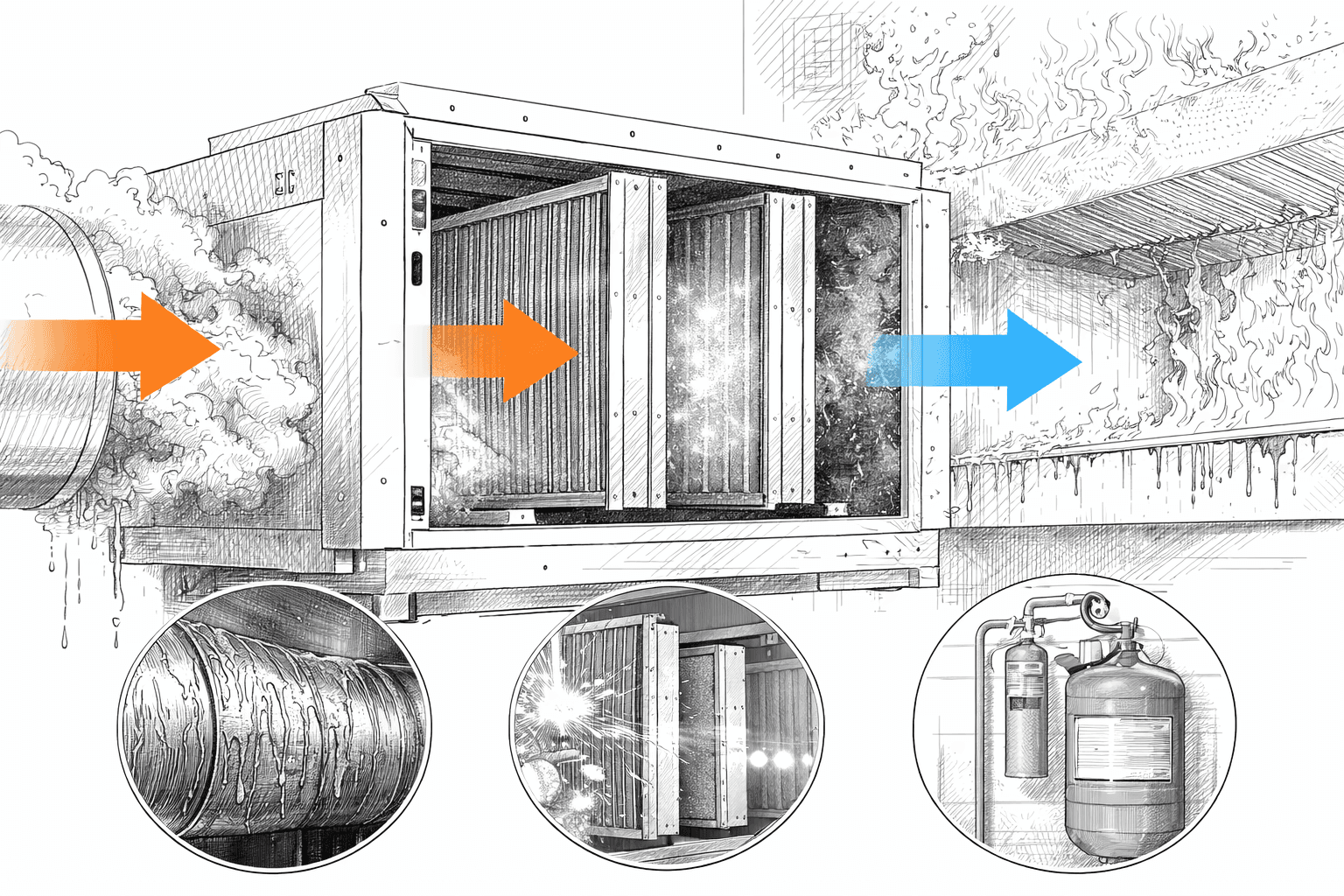

Oil mist is one of the most persistent air-quality challenges in manufacturing environments. Aerosolised coolant and fine oil droplets drift through production areas, coat machines and floors, trigger slip hazards, and degrade indoor air quality (IAQ). When left unmanaged, it leads to increased breakdowns, higher housekeeping costs and unnecessary call-outs.A well-designed combination of staged pre-filtration, ESP and optional HEPA captures these particles efficiently while keeping pressure drop low, ensuring both cleaner air and reliable production.

Where Oil Mist Comes From

Oil mist is a by-product of almost all high-speed metalworking processes. CNC machining, turning, grinding and forming operations generate heat, and coolant is used to manage lubrication and temperature. At high spindle speeds, these coolants atomise into droplets and sub-micron aerosols. Without effective extraction or recirculation filtration, these particles accumulate in the workspace, settle on equipment and enter operators’ breathing zones. The finer the particle, the longer it stays airborne - which is why simple mechanical filters often clog quickly and fail to control IAQ consistently.

System Building Blocks

A robust industrial oil mist system uses multiple stages, each handling a specific contamination load.

Pre-Filters

These catch larger droplets, swarf and bulk contaminants, preventing system overload. Proper pre-filtration protects ESP cells and keeps long-term pressure drop stable.

ESP Modules

Electrostatic precipitators capture fine aerosols with extremely low pressure drop, making them ideal for long-run systems or high-duty production lines. Fan or fanless modules can be used depending on whether the system is connected to existing ductwork or designed as a standalone recirculation unit.

HEPA

When air is being recirculated back into the workspace or when very fine particulate limits apply (e.g., precision manufacturing, sensitive processes, or strict HSE limits), a HEPA final stage ensures compliance. The upstream ESP protects the HEPA from overloading, extending filter life and keeping running costs manageable.

Drain / Collection

Recovered oil should be drained or piped back to a collection point. Proper drainage prevents pooling inside the filtration system and allows for clean reclamation where applicable.

Integration Tips

Good performance starts with correct integration into the production process.

Size systems to capture at source wherever possible - machine hoods, enclosures and localised arms provide the most effective control. For general room IAQ improvements, recirculation units with ESP + HEPA can maintain background air quality without modifying machinery. Use BMS connectivity or machine I/O to link run signals, fault outputs, and safety interlocks, ensuring filtration tracks machine operation. Plan for safe access so operators or FM teams can clean cells without extended stoppages. A well-designed install reduces downtime and keeps routine maintenance predictable.

Service Plan

Regular cleaning is essential to maintain low pressure drop and consistent capture efficiency.Routine washing of ESP cells and pre-filters prevents blockages, stabilises airflow and keeps fans running at lower energy.Maintenance logs support insurance, HSE compliance and machinery warranties, and they help demonstrate proactive IAQ management during audits.

Industrial Oil Mist Filtration: Reduce Downtime & Improve IAQ

Oil mist is one of the most persistent air-quality challenges in manufacturing environments. Aerosolised coolant and fine oil droplets drift through production areas, coat machines and floors, trigger slip hazards, and degrade indoor air quality (IAQ). When left unmanaged, it leads to increased breakdowns, higher housekeeping costs and unnecessary call-outs.A well-designed combination of staged pre-filtration, ESP and optional HEPA captures these particles efficiently while keeping pressure drop low, ensuring both cleaner air and reliable production.

Where Oil Mist Comes From

Oil mist is a by-product of almost all high-speed metalworking processes. CNC machining, turning, grinding and forming operations generate heat, and coolant is used to manage lubrication and temperature. At high spindle speeds, these coolants atomise into droplets and sub-micron aerosols. Without effective extraction or recirculation filtration, these particles accumulate in the workspace, settle on equipment and enter operators’ breathing zones. The finer the particle, the longer it stays airborne - which is why simple mechanical filters often clog quickly and fail to control IAQ consistently.

System Building Blocks

A robust industrial oil mist system uses multiple stages, each handling a specific contamination load.

Pre-Filters

These catch larger droplets, swarf and bulk contaminants, preventing system overload. Proper pre-filtration protects ESP cells and keeps long-term pressure drop stable.

ESP Modules

Electrostatic precipitators capture fine aerosols with extremely low pressure drop, making them ideal for long-run systems or high-duty production lines. Fan or fanless modules can be used depending on whether the system is connected to existing ductwork or designed as a standalone recirculation unit.

HEPA

When air is being recirculated back into the workspace or when very fine particulate limits apply (e.g., precision manufacturing, sensitive processes, or strict HSE limits), a HEPA final stage ensures compliance. The upstream ESP protects the HEPA from overloading, extending filter life and keeping running costs manageable.

Drain / Collection

Recovered oil should be drained or piped back to a collection point. Proper drainage prevents pooling inside the filtration system and allows for clean reclamation where applicable.

Integration Tips

Good performance starts with correct integration into the production process.

Size systems to capture at source wherever possible - machine hoods, enclosures and localised arms provide the most effective control. For general room IAQ improvements, recirculation units with ESP + HEPA can maintain background air quality without modifying machinery. Use BMS connectivity or machine I/O to link run signals, fault outputs, and safety interlocks, ensuring filtration tracks machine operation. Plan for safe access so operators or FM teams can clean cells without extended stoppages. A well-designed install reduces downtime and keeps routine maintenance predictable.

Service Plan

Regular cleaning is essential to maintain low pressure drop and consistent capture efficiency.Routine washing of ESP cells and pre-filters prevents blockages, stabilises airflow and keeps fans running at lower energy.Maintenance logs support insurance, HSE compliance and machinery warranties, and they help demonstrate proactive IAQ management during audits.

Industrial Oil Mist Filtration: Reduce Downtime & Improve IAQ

Oil mist is one of the most persistent air-quality challenges in manufacturing environments. Aerosolised coolant and fine oil droplets drift through production areas, coat machines and floors, trigger slip hazards, and degrade indoor air quality (IAQ). When left unmanaged, it leads to increased breakdowns, higher housekeeping costs and unnecessary call-outs.A well-designed combination of staged pre-filtration, ESP and optional HEPA captures these particles efficiently while keeping pressure drop low, ensuring both cleaner air and reliable production.

Where Oil Mist Comes From

Oil mist is a by-product of almost all high-speed metalworking processes. CNC machining, turning, grinding and forming operations generate heat, and coolant is used to manage lubrication and temperature. At high spindle speeds, these coolants atomise into droplets and sub-micron aerosols. Without effective extraction or recirculation filtration, these particles accumulate in the workspace, settle on equipment and enter operators’ breathing zones. The finer the particle, the longer it stays airborne - which is why simple mechanical filters often clog quickly and fail to control IAQ consistently.

System Building Blocks

A robust industrial oil mist system uses multiple stages, each handling a specific contamination load.

Pre-Filters

These catch larger droplets, swarf and bulk contaminants, preventing system overload. Proper pre-filtration protects ESP cells and keeps long-term pressure drop stable.

ESP Modules

Electrostatic precipitators capture fine aerosols with extremely low pressure drop, making them ideal for long-run systems or high-duty production lines. Fan or fanless modules can be used depending on whether the system is connected to existing ductwork or designed as a standalone recirculation unit.

HEPA

When air is being recirculated back into the workspace or when very fine particulate limits apply (e.g., precision manufacturing, sensitive processes, or strict HSE limits), a HEPA final stage ensures compliance. The upstream ESP protects the HEPA from overloading, extending filter life and keeping running costs manageable.

Drain / Collection

Recovered oil should be drained or piped back to a collection point. Proper drainage prevents pooling inside the filtration system and allows for clean reclamation where applicable.

Integration Tips

Good performance starts with correct integration into the production process.

Size systems to capture at source wherever possible - machine hoods, enclosures and localised arms provide the most effective control. For general room IAQ improvements, recirculation units with ESP + HEPA can maintain background air quality without modifying machinery. Use BMS connectivity or machine I/O to link run signals, fault outputs, and safety interlocks, ensuring filtration tracks machine operation. Plan for safe access so operators or FM teams can clean cells without extended stoppages. A well-designed install reduces downtime and keeps routine maintenance predictable.

Service Plan

Regular cleaning is essential to maintain low pressure drop and consistent capture efficiency.Routine washing of ESP cells and pre-filters prevents blockages, stabilises airflow and keeps fans running at lower energy.Maintenance logs support insurance, HSE compliance and machinery warranties, and they help demonstrate proactive IAQ management during audits.

Call Us Now

London Office Address:

London Phone Number:

Email Address:

Call Us Now

London Phone Number:

Email Address:

Call Us Now

London Office Address:

London Phone Number:

Email Address: