Automotive & Aerospace

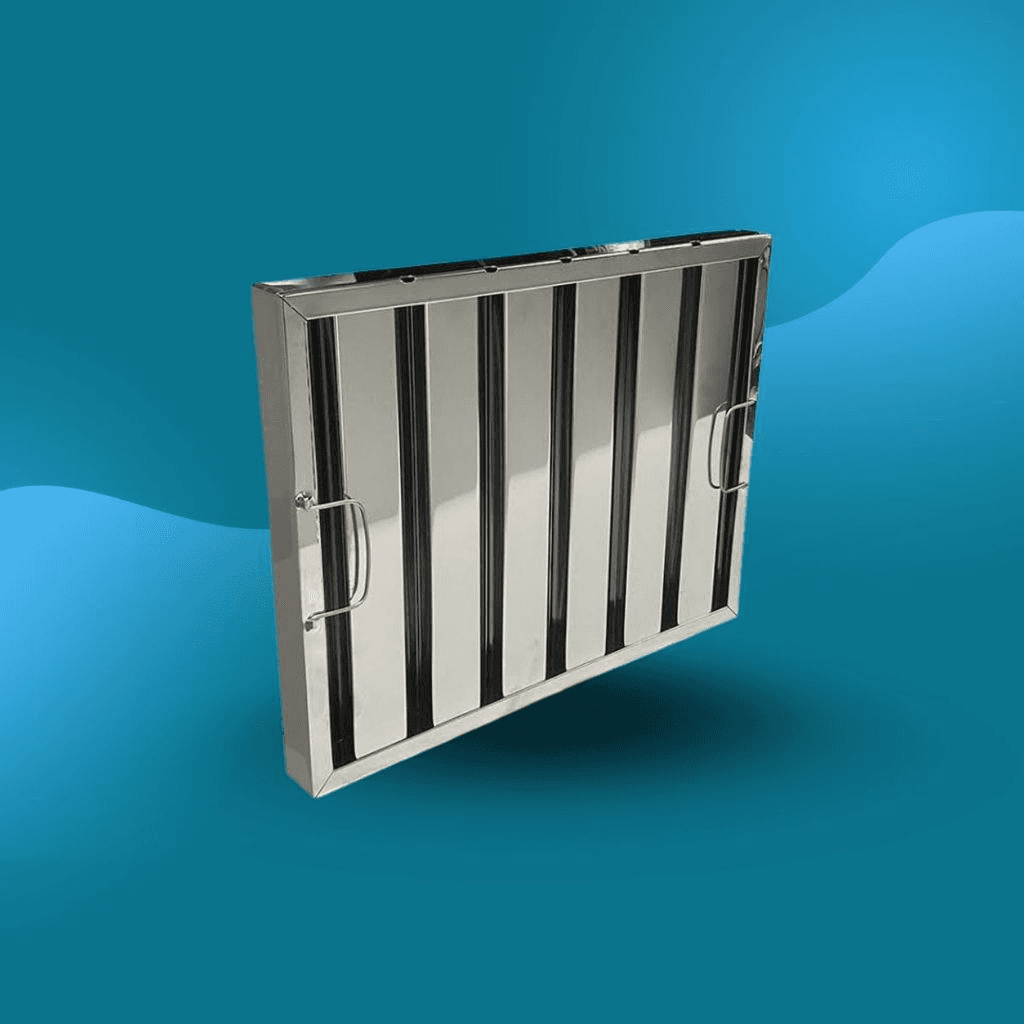

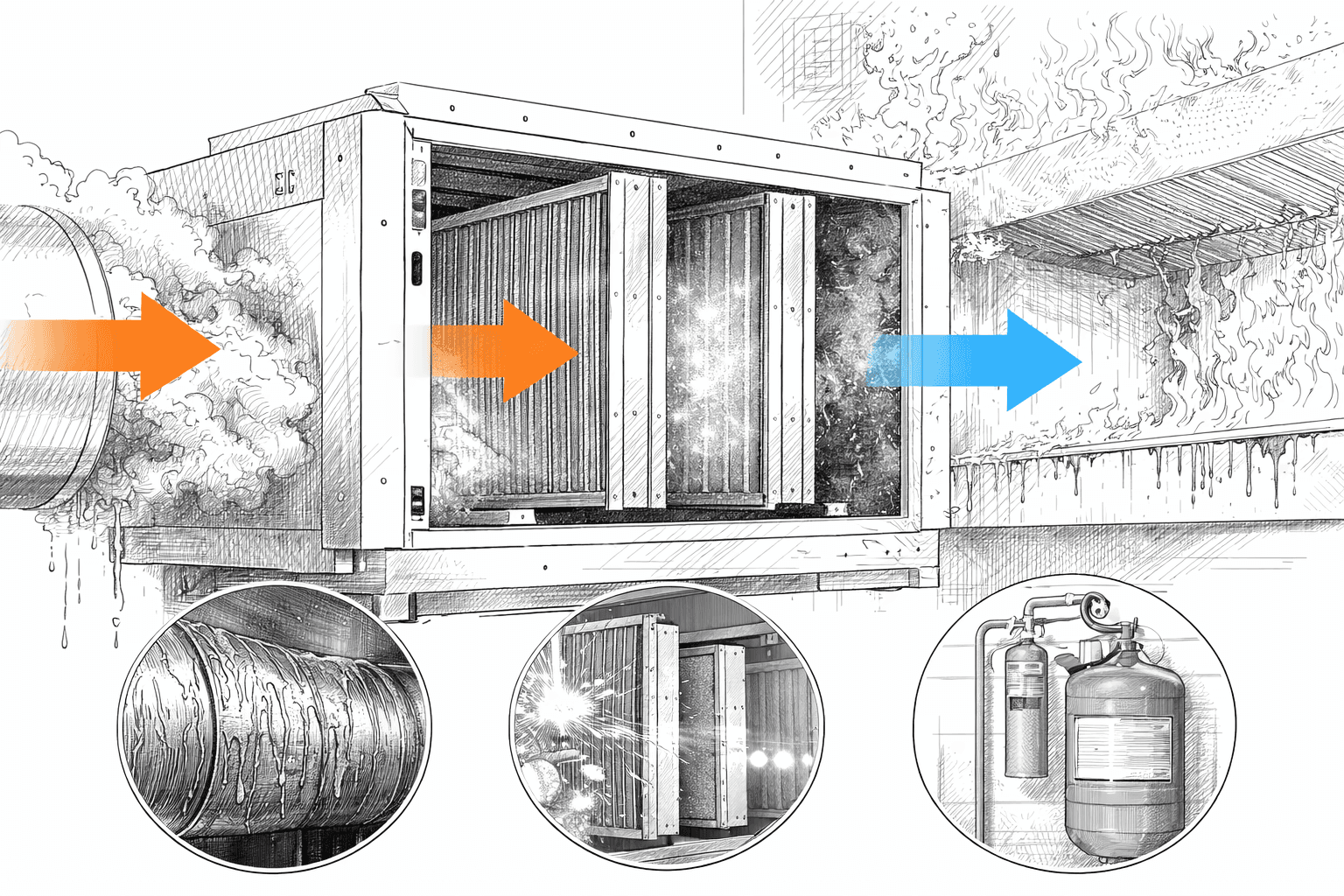

Combine ESP, mist collection and post‑filters to control aerosols, fines and odours from production and finishing processes.

Automotive & Aerospace

Automotive & Aerospace operations depend on precisely controlled air quality to protect finishing, assembly and testing processes. We deliver high-efficiency filtration systems designed to maintain clean, stable environments in paint shops, assembly lines, and high-sensitivity production areas. We offer supply-only units, system upgrades and ongoing maintenance.

Why Filtration Matters in Automotive & Aerospace

High-performance filtration is essential to maintain precision, quality, and equipment reliability in controlled manufacturing environments.

Protects precision and finish quality

Prevents particulates from affecting paints, coatings, sealants, and tight assembly tolerances.

Ensures consistent production standards

Maintains controlled air conditions critical for repeatable, high-quality output.

Extends equipment lifespan

Reduces contamination of HVAC, extraction, and specialist systems—improving uptime and lowering wear.

The problem

Prevents particulates from affecting paints, coatings, sealants, and tight assembly tolerances.

Ensures consistent production standards

Maintains controlled air conditions critical for repeatable, high-quality output.

Extends equipment lifespan

Reduces contamination of HVAC, extraction, and specialist systems—improving uptime and lowering wear.

Protects precision and finish quality

Prevents particulates from affecting paints, coatings, sealants, and tight assembly tolerances.

Ensures consistent production standards

Maintains controlled air conditions critical for repeatable, high-quality output.

Extends equipment lifespan

Reduces contamination of HVAC, extraction, and specialist systems—improving uptime and lowering wear.

Need Systems That Are Ready to Install and Comply?

Get compliant, high-performance systems backed by UK stock, fast support, and direct access to experienced engineers.

Need Systems That Are Ready to Install and Comply?

Get compliant, high-performance systems backed by UK stock, fast support, and direct access to experienced engineers.

Need Systems That Are Ready to Install and Comply?

Get compliant, high-performance systems backed by UK stock, fast support, and direct access to experienced engineers.

How We Work With Automotive & Aerospace Clients

Collaborative design: We engage directly with engineering teams to understand process requirements, clean-air tolerances and airflow conditions before specifying HEPA, MFU, bag or carbon solutions. Specialist experience + support: We’ve delivered solutions for automotive plants, aerospace component manufacturing and precision engineering facilities. Clients can procure systems on a supply-only basis, with optional commissioning support and structured maintenance services.

Proven Systems. Personal Service.

The Trusted Choice for Installers & Consultants

Performance Superiority

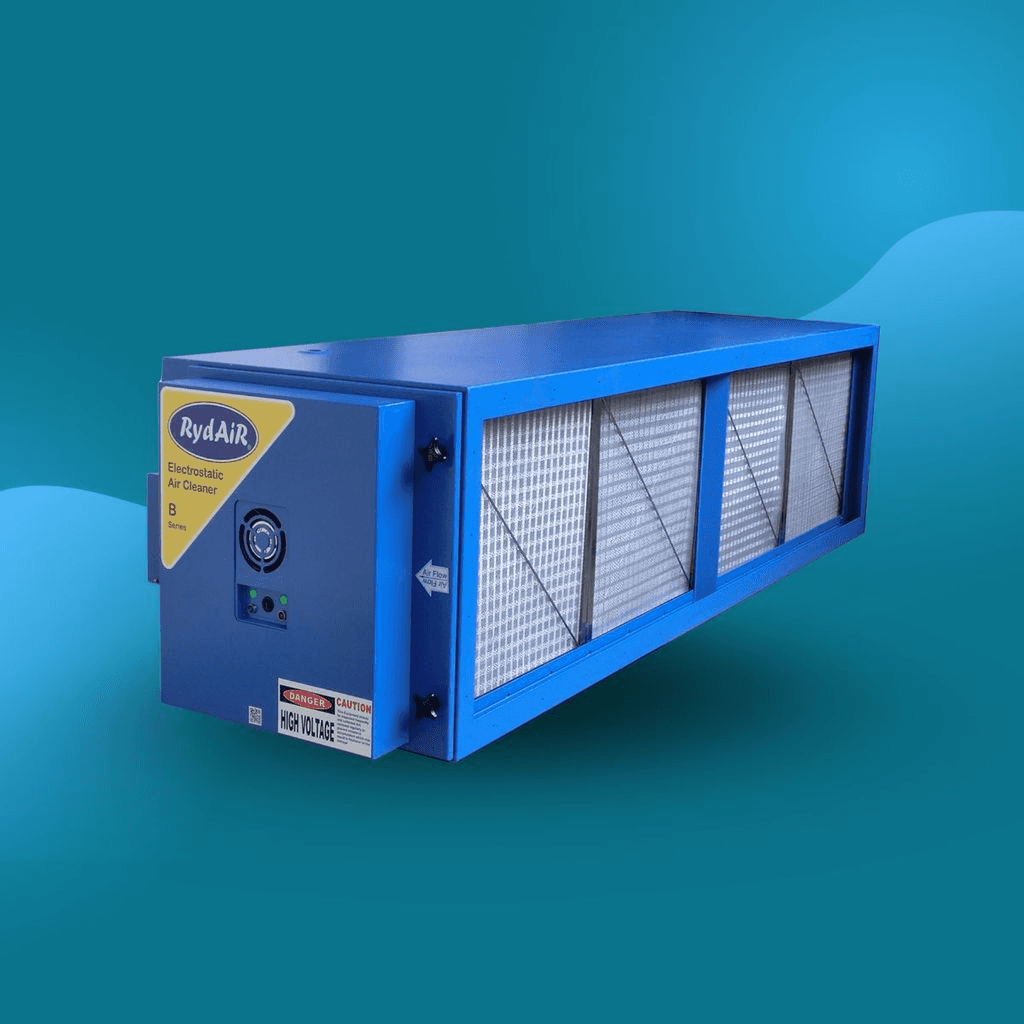

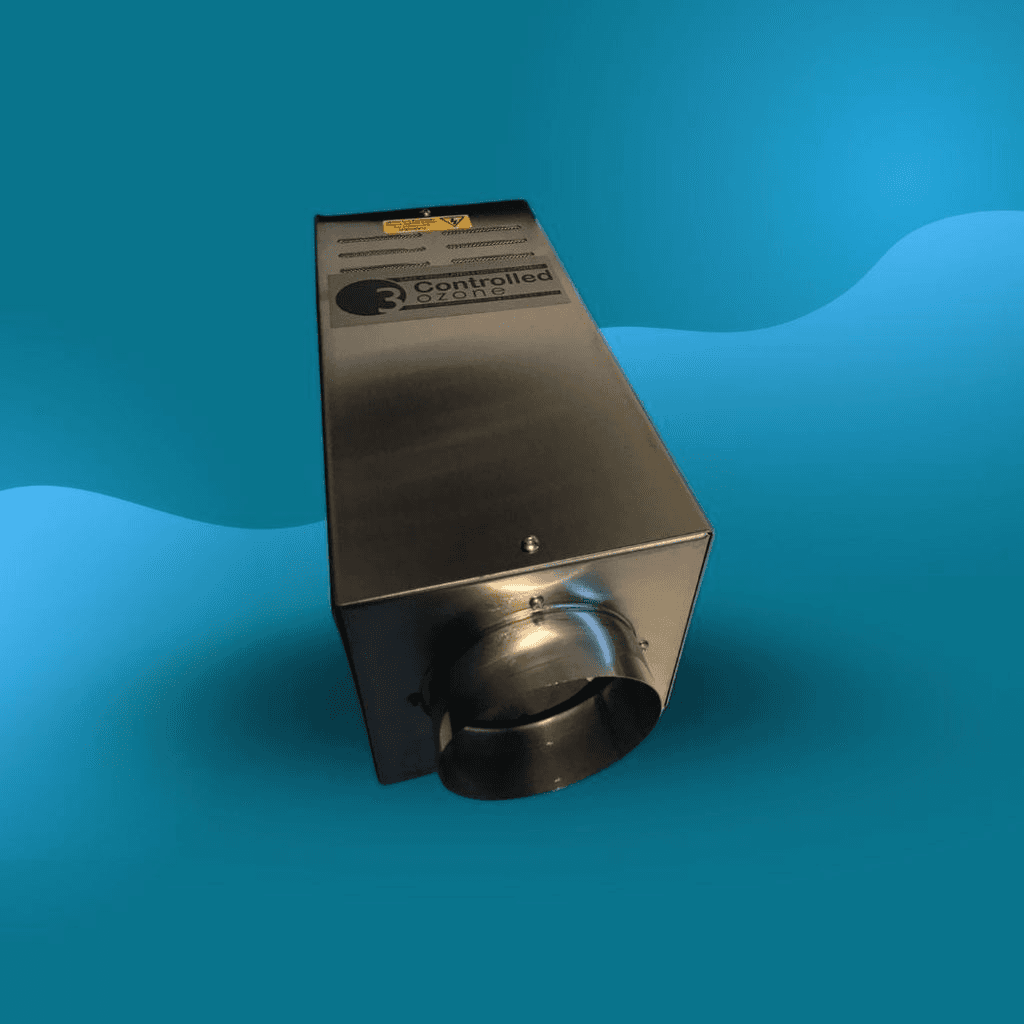

DW/172 and EMAQ compliant ESPs delivering 95%+ single-pass capture, tested to exceed DEFRA odour and particulate guidance.

Regulatory Confidence

Built around UK standards — DW/172, EMAQ and DEFRA — for full compliance in kitchen ventilation and air quality systems.

Personal Service

Washable components, longer filter life and low-pressure-drop design reduce maintenance and energy use.

Proven Systems. Personal Service.

The Trusted Choice for Installers & Consultants

Performance Superiority

DW/172 and EMAQ compliant ESPs delivering 95%+ single-pass capture, tested to exceed DEFRA odour and particulate guidance.

Regulatory Confidence

Built around UK standards — DW/172, EMAQ and DEFRA — for full compliance in kitchen ventilation and air quality systems.

Personal Service

Washable components, longer filter life and low-pressure-drop design reduce maintenance and energy use.

Proven Systems. Personal Service.

The Trusted Choice for Installers & Consultants

Performance Superiority

DW/172 and EMAQ compliant ESPs delivering 95%+ single-pass capture, tested to exceed DEFRA odour and particulate guidance.

Regulatory Confidence

Built around UK standards — DW/172, EMAQ and DEFRA — for full compliance in kitchen ventilation and air quality systems.

Personal Service

Washable components, longer filter life and low-pressure-drop design reduce maintenance and energy use.

Explore

our

range

of

filtration

Solutions

for

Automotive & Aerospace

+

Proven expertise built over two decade in air filtration.

+

Trusted nationwide with thousands of successful installations.

%

Industry-leading efficiency, capturing more than 95% of smoke and grease.

Explore

our

range

of

filtration

Solutions

for

Automotive & Aerospace

+

Proven expertise built over two decade in air filtration.

+

Trusted nationwide with thousands of successful installations.

%

Industry-leading efficiency, capturing more than 95% of smoke and grease.

Explore

our

range

of

filtration

Solutions

for

Automotive & Aerospace

+

Proven expertise built over two decade in air filtration.

+

Trusted nationwide with thousands of successful installations.

%

Industry-leading efficiency, capturing more than 95% of smoke and grease.

What Our Clients Say

5.0

“Great support and service!”

5.0

"I have had excellent service and communication from Extechnology"

5.0

“Great company to work with. Nothing is too much trouble”

5.0

“Great service and industry leading advice"

5.0

“Great support and service!”

5.0

“Excellent customer service”

5.0

"Great company to work with. Nothing is too much trouble"

What Our Clients Say

5.0

“Great support and service!”

5.0

"I have had excellent service and communication from Extechnology"

5.0

“Great company to work with. Nothing is too much trouble”

5.0

“Great service and industry leading advice"

5.0

“Great support and service!”

5.0

“Excellent customer service”

5.0

"Great company to work with. Nothing is too much trouble"

What Our Clients Say

5.0

“Great support and service!”

5.0

"I have had excellent service and communication from Extechnology"

5.0

“Great company to work with. Nothing is too much trouble”

5.0

“Great service and industry leading advice"

5.0

“Great support and service!”

5.0

“Excellent customer service”

5.0

"Great company to work with. Nothing is too much trouble"

Call Us Now

London Office Address:

London Phone Number:

Email Address:

Call Us Now

London Phone Number:

Email Address:

Call Us Now

London Office Address:

London Phone Number:

Email Address: