Sep 16, 2025

ESP, Carbon & Ozone: Building a Compliant Kitchen Extract System in the UK

Dan Clark

Technical Director, X Technology

How to combine electrostatic precipitation (ESP), activated carbon and optional ozone/UV‑C to control grease, smoke and odour in UK kitchens while aligning with TR19 and EMAQ planning.

Sep 16, 2025

ESP, Carbon & Ozone: Building a Compliant Kitchen Extract System in the UK

Dan Clark

Technical Director, X Technology

How to combine electrostatic precipitation (ESP), activated carbon and optional ozone/UV‑C to control grease, smoke and odour in UK kitchens while aligning with TR19 and EMAQ planning.

Sep 16, 2025

ESP, Carbon & Ozone: Building a Compliant Kitchen Extract System in the UK

Dan Clark

Technical Director, X Technology

How to combine electrostatic precipitation (ESP), activated carbon and optional ozone/UV‑C to control grease, smoke and odour in UK kitchens while aligning with TR19 and EMAQ planning.

ESP, Carbon & Ozone: Building a Compliant Kitchen Extract System in the UK

Designing a Compliant Kitchen Extract: ESP, Carbon & Ozone Working Together

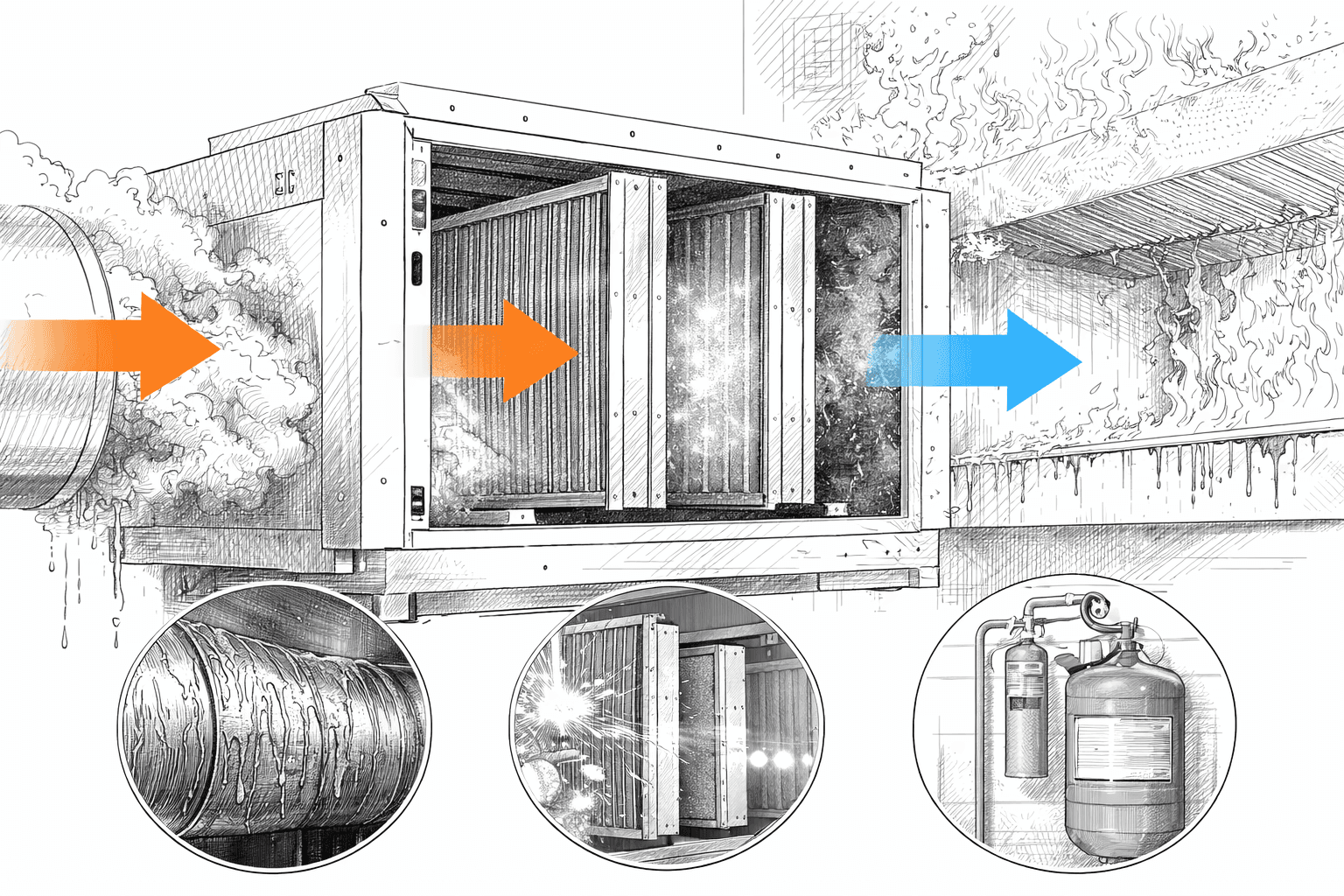

For most commercial kitchens in the UK, reliable odour and grease control demands a layered approach. " "Electrostatic precipitation (ESP) removes particulates with low pressure drop, ozone/UV‑C helps break down odorous compounds, " "and activated carbon polishes remaining VOCs before discharge. When sized and maintained correctly, this train aligns with " "TR19 hygiene good practice and common EMAQ/DEFRA expectations at planning stage.

Who this guide is for

M&E consultants preparing specifications and compliance statements. Mechanical contractors tasked with delivering a predictable, low‑risk solution. Restaurant groups and independent operators who need fewer complaints and lower running costs.

The treatment train (typical)

ESP — captures grease and smoke particulates; keeps downstream ducts cleaner and protects carbon media. Ozone/UV‑C (optional) — oxidises odorous compounds and reduces carbon loading, particularly useful for charcoal/heavy cooking and late trading. Activated carbon — final polishing step; dwell time is key to consistent neighbour‑friendly discharge.

Design principles that prevent issues

Airflow & dwell time : size the ESP for duty CMH with margin; set carbon face velocity to achieve meaningful contact time. Pressure drop (ΔP) : ESP adds minimal ΔP; include allowances for pre‑filters and fouling. Keep the system inside the fan curve. Safety & interlocks : door interlocks, airflow proving, and BMS status/fault terminals reduce call‑outs. Drainage & access : service doors, removable cells and sumps make cleaning safe and quick. Discharge strategy : where possible, discharge above roof level and well away from air intakes and sensitive receptors.

Maintenance schedule (typical)

Item Action Interval (guide) Pre‑filters Wash with warm water/degreaser; dry fully 1–4 weeks ESP cells Soak/wash with approved alkaline cleaner; rinse & dry 4–8 weeks (heavy loads more often) Carbon Replace before breakthrough; log change‑outs As required by odour performance UV‑C/ozone Replace lamps around 12,000–13,000 hrs; verify interlocks Annually or per runtime

Documentation & compliance

Provide commissioning evidence (airflow, ΔP, leakage checks) alongside a documented cleaning plan and logbook. This " "supports TR19 hygiene audits and typical planning conditions informed by EMAQ/DEFRA guidance. " "Link the maintenance schedule to your planned maintenance provider to avoid drift.

Common pitfalls to avoid

Specifying carbon without controlling particulates first — media blocks early, odour returns, and energy use climbs. Under‑sizing ESP or carbon dwell time — initial performance looks fine, but complaints arise at peak load or after fouling. No interlocks — ozone without airflow proving and door interlocks is a safety and compliance risk.

Next steps

Explore our ESP range and carbon modules. Request a free odour assessment and treatment schematic. Bundle with Arden Environmental maintenance for guaranteed uptime.

FAQs

Do I always need ozone? No — it’s most valuable for persistent odours, charcoal grills and long duct runs. We risk‑assess site by site.

Will ESP remove odour? ESP targets particulates; odour control typically requires carbon and/or ozone.

Is the system noisy? ESP itself has no moving parts; total noise depends on fan selection and layout.

ESP, Carbon & Ozone: Building a Compliant Kitchen Extract System in the UK

Designing a Compliant Kitchen Extract: ESP, Carbon & Ozone Working Together

For most commercial kitchens in the UK, reliable odour and grease control demands a layered approach. " "Electrostatic precipitation (ESP) removes particulates with low pressure drop, ozone/UV‑C helps break down odorous compounds, " "and activated carbon polishes remaining VOCs before discharge. When sized and maintained correctly, this train aligns with " "TR19 hygiene good practice and common EMAQ/DEFRA expectations at planning stage.

Who this guide is for

M&E consultants preparing specifications and compliance statements. Mechanical contractors tasked with delivering a predictable, low‑risk solution. Restaurant groups and independent operators who need fewer complaints and lower running costs.

The treatment train (typical)

ESP — captures grease and smoke particulates; keeps downstream ducts cleaner and protects carbon media. Ozone/UV‑C (optional) — oxidises odorous compounds and reduces carbon loading, particularly useful for charcoal/heavy cooking and late trading. Activated carbon — final polishing step; dwell time is key to consistent neighbour‑friendly discharge.

Design principles that prevent issues

Airflow & dwell time : size the ESP for duty CMH with margin; set carbon face velocity to achieve meaningful contact time. Pressure drop (ΔP) : ESP adds minimal ΔP; include allowances for pre‑filters and fouling. Keep the system inside the fan curve. Safety & interlocks : door interlocks, airflow proving, and BMS status/fault terminals reduce call‑outs. Drainage & access : service doors, removable cells and sumps make cleaning safe and quick. Discharge strategy : where possible, discharge above roof level and well away from air intakes and sensitive receptors.

Maintenance schedule (typical)

Item Action Interval (guide) Pre‑filters Wash with warm water/degreaser; dry fully 1–4 weeks ESP cells Soak/wash with approved alkaline cleaner; rinse & dry 4–8 weeks (heavy loads more often) Carbon Replace before breakthrough; log change‑outs As required by odour performance UV‑C/ozone Replace lamps around 12,000–13,000 hrs; verify interlocks Annually or per runtime

Documentation & compliance

Provide commissioning evidence (airflow, ΔP, leakage checks) alongside a documented cleaning plan and logbook. This " "supports TR19 hygiene audits and typical planning conditions informed by EMAQ/DEFRA guidance. " "Link the maintenance schedule to your planned maintenance provider to avoid drift.

Common pitfalls to avoid

Specifying carbon without controlling particulates first — media blocks early, odour returns, and energy use climbs. Under‑sizing ESP or carbon dwell time — initial performance looks fine, but complaints arise at peak load or after fouling. No interlocks — ozone without airflow proving and door interlocks is a safety and compliance risk.

Next steps

Explore our ESP range and carbon modules. Request a free odour assessment and treatment schematic. Bundle with Arden Environmental maintenance for guaranteed uptime.

FAQs

Do I always need ozone? No — it’s most valuable for persistent odours, charcoal grills and long duct runs. We risk‑assess site by site.

Will ESP remove odour? ESP targets particulates; odour control typically requires carbon and/or ozone.

Is the system noisy? ESP itself has no moving parts; total noise depends on fan selection and layout.

ESP, Carbon & Ozone: Building a Compliant Kitchen Extract System in the UK

Designing a Compliant Kitchen Extract: ESP, Carbon & Ozone Working Together

For most commercial kitchens in the UK, reliable odour and grease control demands a layered approach. " "Electrostatic precipitation (ESP) removes particulates with low pressure drop, ozone/UV‑C helps break down odorous compounds, " "and activated carbon polishes remaining VOCs before discharge. When sized and maintained correctly, this train aligns with " "TR19 hygiene good practice and common EMAQ/DEFRA expectations at planning stage.

Who this guide is for

M&E consultants preparing specifications and compliance statements. Mechanical contractors tasked with delivering a predictable, low‑risk solution. Restaurant groups and independent operators who need fewer complaints and lower running costs.

The treatment train (typical)

ESP — captures grease and smoke particulates; keeps downstream ducts cleaner and protects carbon media. Ozone/UV‑C (optional) — oxidises odorous compounds and reduces carbon loading, particularly useful for charcoal/heavy cooking and late trading. Activated carbon — final polishing step; dwell time is key to consistent neighbour‑friendly discharge.

Design principles that prevent issues

Airflow & dwell time : size the ESP for duty CMH with margin; set carbon face velocity to achieve meaningful contact time. Pressure drop (ΔP) : ESP adds minimal ΔP; include allowances for pre‑filters and fouling. Keep the system inside the fan curve. Safety & interlocks : door interlocks, airflow proving, and BMS status/fault terminals reduce call‑outs. Drainage & access : service doors, removable cells and sumps make cleaning safe and quick. Discharge strategy : where possible, discharge above roof level and well away from air intakes and sensitive receptors.

Maintenance schedule (typical)

Item Action Interval (guide) Pre‑filters Wash with warm water/degreaser; dry fully 1–4 weeks ESP cells Soak/wash with approved alkaline cleaner; rinse & dry 4–8 weeks (heavy loads more often) Carbon Replace before breakthrough; log change‑outs As required by odour performance UV‑C/ozone Replace lamps around 12,000–13,000 hrs; verify interlocks Annually or per runtime

Documentation & compliance

Provide commissioning evidence (airflow, ΔP, leakage checks) alongside a documented cleaning plan and logbook. This " "supports TR19 hygiene audits and typical planning conditions informed by EMAQ/DEFRA guidance. " "Link the maintenance schedule to your planned maintenance provider to avoid drift.

Common pitfalls to avoid

Specifying carbon without controlling particulates first — media blocks early, odour returns, and energy use climbs. Under‑sizing ESP or carbon dwell time — initial performance looks fine, but complaints arise at peak load or after fouling. No interlocks — ozone without airflow proving and door interlocks is a safety and compliance risk.

Next steps

Explore our ESP range and carbon modules. Request a free odour assessment and treatment schematic. Bundle with Arden Environmental maintenance for guaranteed uptime.

FAQs

Do I always need ozone? No — it’s most valuable for persistent odours, charcoal grills and long duct runs. We risk‑assess site by site.

Will ESP remove odour? ESP targets particulates; odour control typically requires carbon and/or ozone.

Is the system noisy? ESP itself has no moving parts; total noise depends on fan selection and layout.

Call Us Now

London Office Address:

London Phone Number:

Email Address:

Call Us Now

London Phone Number:

Email Address:

Call Us Now

London Office Address:

London Phone Number:

Email Address: